When it comes to cybersecurity, the question is if, not when, you’ll be under threat from malicious actors. In fact, manufacturing is the target for nearly one-quarter of ransomware attacks. Given that the owners, managers, and supervisors of small jobs shops and manufacturers often act as the IT staff, they don’t have the in-house expertise to establish best practices, nor do they have budget to hire expensive consultants.

Fortunately, there are trusted no- to low-cost resources and solutions — and that’s the focus of Season 2, Episode 1 Part 1 and Part 2 of the IMTS+ Original Series “Smart(er) Shop,” brought to you by Autodesk.

“Smart(er) Shop” features Adam Allard, senior manager of technical environments at Autodesk Research, who oversees Autodesk Technology Centers in Toronto, San Francisco, and Boston, and me, Ryan Kelly, the general manager for AMT’s San Francisco Tech Lab, and. Its mission is to provide easy-to-deploy ideas for manufacturers, such as those offered by MxD, the nation’s digital manufacturing and cybersecurity institute based in Chicago. The organization is part of the trusted Manufacturing USA network, and MxD offers a free cybersecurity playbook that anyone can implement.

For shops pursuing Cybersecurity Maturity Model Certification (CMMC 2.0) to obtain defense contracts, the visit to MxD is a must-watch, two-part episode of “Smart(er) Shop.” To highlight six no- or low-cost cybersecurity practices, Allard and I connect with MxD’s senior director of cybersecurity.

What makes this two-part episode so powerful is that MxD is organized as a demonstration facility featuring equipment and systems familiar to manufacturers. Members of the MxD team literally walk us through cybersecurity challenges and best practices, starting with physical security measures to provide authorized access. Part 1 of this episode also covers:

“Role-based access control” for logging into a computer connected to a network

Measures to stop connecting unauthorized hardware or installing unauthorized software (sorry, no sports betting apps on that work computer)

Features a cyber process test bed that simulates a water purification process

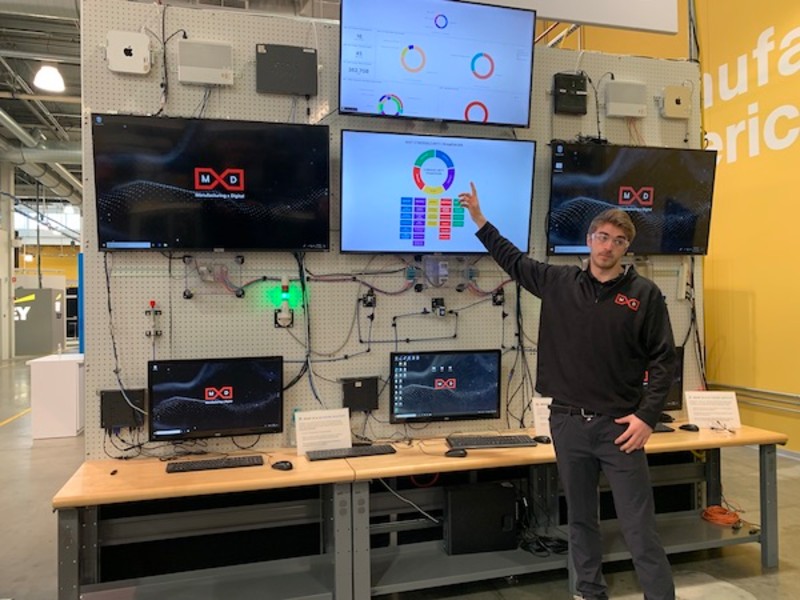

Part 2 of the episode further builds out the cybersecurity framework, starting with USB and other removable media. As an example, MxD protected the SD card slot for its 3D printer with a physical lock designed in house and printed on the machine it protects. Next, MxD’s “cyber wall” demonstrates what security looks like in an average shop — and how to make it better with “allow-listing software” that prevents malware from running. The last stop on the MxD factory floor tour simulates a “special use” environment, which may be required for U.S. Department of Defense work or for areas with restricted access due to the presence of materials such as certain metal powders used for additive manufacturing.

The episode concludes with the free tools available on the MxD Cyber Resource Hub, and I learn a painful lesson about what happens to people who leave their visitor passes behind (yes, you do need those stinking badges).

In addition to cybersecurity, Season 2 of “Smart(er) Shop” features Episode 2 on connected solutions for manufacturers of all sizes, and Episode 3 highlights a low-cost “robots-as-a-service” solution for a vexing QC scenario. Watch all episodes at IMTS.com/SmarterShop.