By now, you’ve certainly heard of digital twin. The term took off in 2012-2013 and has been climbing in popularity quickly and consistently ever since – despite a slight hiccup in 2020. I wonder what that could have been?

We’ll come back to this, but the key takeaway is that digital twin is kind of hype right now.

At this year’s IMTS, we saw a handful of tech companies that we haven’t typically seen at previous shows. And even makers of graphics cards? What gives? What were they doing here? What the heck do they have to do with manufacturing technology? They don’t even make their own silicon! I thought TSMC, SK Hynix, and Samsung did that for them. Slow down, bro. Chill.

Digital twins are why they were here. 3D graphics collaboration platforms like Nvidia's Omniverse heavily rely on Universal Scene Description (USD) to enable its functions and features. USD, developed by Pixar, is a framework that allows for the interchange of 3D computer graphics data. It facilitates collaboration across various tools and platforms in real time, enhancing productivity and innovation in industries ranging from architecture to manufacturing to entertainment.

OpenUSD and USD refer to the same core technology, with OpenUSD emphasizing the framework's open-source nature. Pixar developed USD in the early 2010s as an internal tool for their own non-linear animation workflows. The framework was introduced to the public in 2016, when Pixar released OpenUSD as open-source software. This move aimed to provide the broader graphics and animation community with a powerful tool for managing complex 3D scenes and facilitating collaborative workflows across various platforms and applications.

Hmm… Complex 3D scenes. Collaborative workflows. Platform and application integration. This is starting to smell suspiciously like digital manufacturing. And that, in fact, is right at the heart of all this. Virtual worlds for gaming, entertainment, and social media are built with a set of tools that are mostly untested in industrial use cases. We already have camera glasses and headsets for remote maintenance and assembly, but they are far from common. Can using the tools already built by other, seemingly unrelated, industries help make virtual manufacturing more useful?

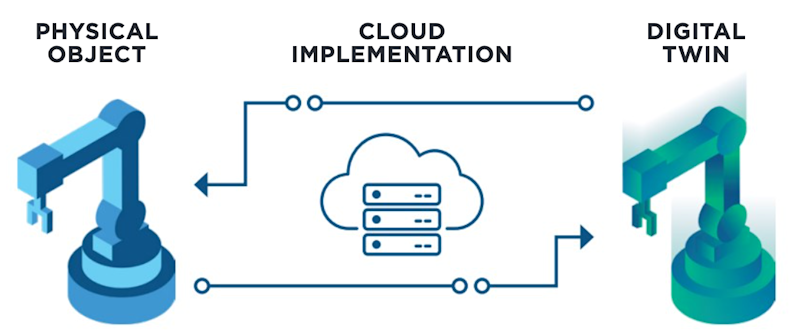

So, imagine it. Manufacturing technology and machines from different manufacturers, brands, and even eras from different corners of the globe all interacting virtually – and seamlessly – to test, develop, and fine-tune processes to maximize a single shop floor’s efficiency. A digital twin of your factory filled with the digital twins of your machinery. They just need a virtual standard language and set of tools to get it going.

The keyword here is “standard.” OpenUSD is not a standard – yet. So, returning to the hype that is the digital twin and its ever-expanding universe: We need a standard. OpenUSD will be that standard. By now, you’ve heard it a lot, but hunker down because you’re about to hear it a lot more – at least until the next IMTS in 2026. But remember: You heard it here first – and I’ll die on that hill. LaMarca out.

To read the rest of the Space Issue of MT Magazine, click here.