“Just because something doesn’t do what you planned it to do doesn’t mean it’s useless.”

– Thomas Edison

This is a published version of the AMT Tech Report newsletter. You can sign up to get the Tech Report in your inbox here.

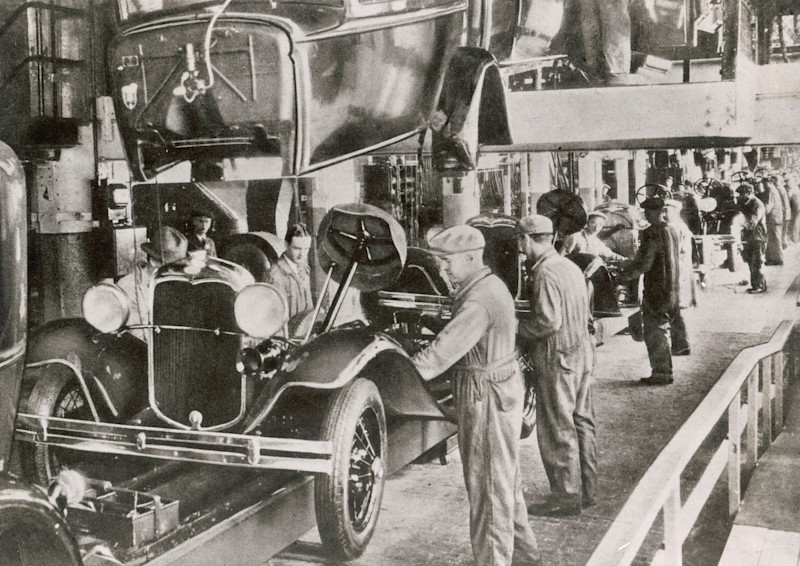

1. Ford Hits Alt + F4 on the Assembly Line

Ford is putting $2 billion into its Louisville plant to replace the century-old moving line with a three-branch “universal production system” for affordable EVs. The first, a $30,000 midsize pickup, launches in 2027. Using large unicastings, modular kits, and fewer parts, the process is 15% faster and cuts components by 20%. With UAW buy-in, Ford’s bet aims to make EVs cheaper, safer to build, and competitive with global rivals by closing the old program and opening a new one.

2. RealSense Goes Solo, Sees Big Picture

Freshly spun out from Intel, RealSense raised $50 million to push its AI-powered vision tech deeper into robotics, biometrics, and automation. Known for depth cameras embedded in 60% of AMRs and humanoid robots, RealSense is scaling manufacturing, adding engineers, and chasing fast growth in robotics and facial biometrics. With products like the new D555 depth camera and a portfolio that’s 80 patents deep, it’s aiming to make machines see and work smarter, safer, and more reliably.

3. Screen to Spindle

Great CAM and simulation don’t guarantee great parts! The handoff from engineering to the shop floor matters just as much. Missing setup details, unclear offsets, and mismatched speeds and feeds can turn a perfect virtual toolpath into scrap. A solid process will document fixtures, tooling, probing, and risk checks so the real-world run matches the digital plan. Nail the translation, and you’ll stop fixing parts that looked fine on screen. This is the way – the Way of the Mill.

4. Quantum National Security

Sandia National Labs is the first national lab to join the National Semiconductor Technology Center, where it will push chiplet design, quantum-ready processors, and STEM workforce growth. With CHIPS Act backing, its MESA (Microsystems Engineering, Science, and Applications) facility is working to secure advanced chip production, share high-security R&D resources, and train the next wave of scientists. The goal: Keep the United States ahead in the chip game and avoid any Half-Life-style “unexpected consequences.”

5. The Economy’s Not Itself When It’s Hungry

Mars Wrigley is putting $2 billion into U.S. manufacturing by 2026, adding capacity for candy, snacks, and pet food while boosting domestic production above its current 94%. Projects include a new Nature’s Bakery plant in Utah and the world’s largest Royal Canin dry pet food facility in Ohio. With automation upgrades and a reshoring push, Mars aims to innovate faster, cut supply risks, and meet demand.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To hear the latest in additive manufacturing, material removal, automation, and digital manufacturing, subscribe to the AMT Tech Trends podcast here.