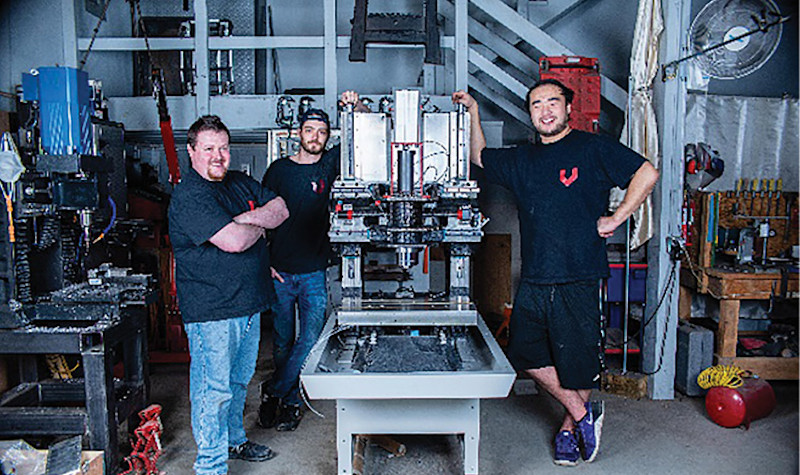

Vulcan Machine Co., a manufacturing startup founded by three recent James Madison University (JMU) graduates, successfully pivoted and expanded their operational scope twice to take advantage of market opportunities. In the July 27 AMT digital newsletter, we reported that three years ago, the company founders were in the process of developing large-format, industrial 3D printers in JMU’s X-Labs makerspace when they discovered a major opportunity in the CNC milling market and successfully changed direction to meet that market need.

Through interviewing potential customers while developing their 3D printers, they realized a major gap existed in the CNC machining industry. Their customer discovery and market research led them to discover that many small manufacturers and startups often need increased production capabilities, but do not have the startup capital nor floorspace to purchase robust, industrial-caliber milling machines for prototyping and small-batch production. Vulcan developed a compact, cast iron, precision CNC mill for micro-fabricators and small businesses that need to create professional-level parts in-house affordably.

The coronavirus hit just when their original foundry, located in Wuhan, China, had put the castings of their first mill in the factory yard to cool, and they remained there for the next two months while Wuhan was on lockdown. While waiting for the castings to be shipped to their shop in Virginia, the Vulcan team made the most of their downtime as they discovered and pursued another major opportunity – sourcing PPE for front line workers – which ultimately led them to start a new company to manufacture three-ply facemasks locally in Virginia.

“Our involvement in sourcing PPE started as a volunteer effort when we learned that a number of our suppliers were retooling to produce PPE,” said Chris Ashley, co-founder, Vulcan Machine Co. “We realized that we could also play an important role in sourcing these much-needed supplies as we already had relationships and connections to get the supplies tested, imported, and distributed in the United States.”

Vulcan PPE LLC is born

As the number of companies and organizations contacting them to buy PPE grew, they realized that producing PPE could become a viable business opportunity.

Early on, the decision was made to be fully transparent about materials and pricing. Stories were coming out in the media about unethical practices such as price gouging, fraudulent products, and companies being paid for orders that were never delivered, and they wanted to be clear that their supplies were certified and fairly priced.

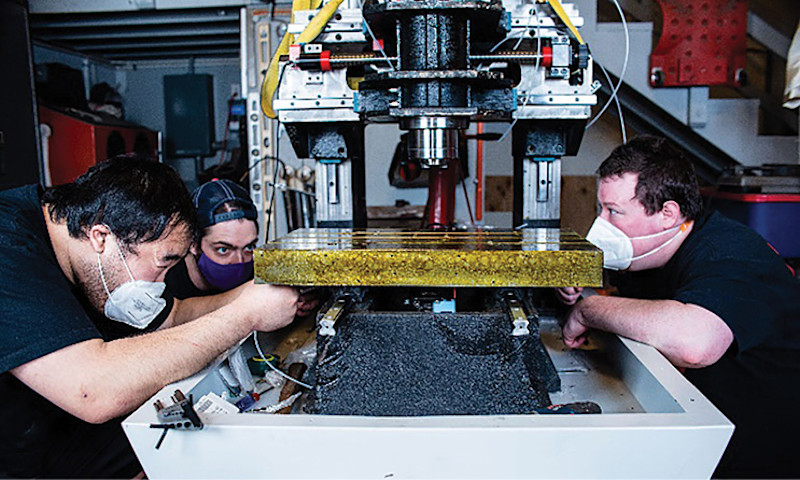

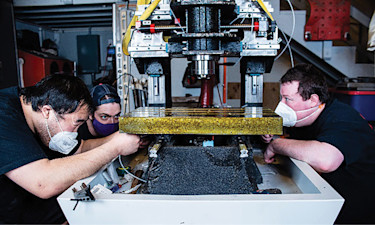

The Vulcan team was able to successfully secure sources for all of the main categories of PPE – gloves, disposable and form-fitting facemasks, respirator masks, face shields, and gowns – and began supplying research labs, hospitals, schools, the state of Virginia, and private sector companies. To date, Vulcan has delivered three-quarters of a million masks and face shields.

“When we began sourcing PPE, we thought of it as a short-term opportunity, helping to meet national needs in a time of crisis,” said Ashley. “We now realize that it is a longer-term opportunity because even after a successful vaccine is developed, most hospitals, states, and the U.S. government will be building a stockpile of PPE to buffer against any future health pandemics.”

In order to keep both companies on schedule, the Vulcan PPE team expanded to bring on a career logistics specialist, a medical professional, a prior Amazon and Microsoft executive, and a retired army Colonel as partners to help stand up and scale the business. Bringing on these additional partners has allowed the original Vulcan team to shift their focus back to beta testing and ultimately launching presales for their compact precision CNC mill.

Vulcan PPE is currently in the process of starting up its factory in Virginia to manufacture three-ply disposable surgical masks, and it is slated to be up and running by the middle of September, producing close to 100,000 masks per day. An e-commerce enabled site – Vulcanppe.com – will make it easier for small businesses to place orders in the range of thousands of pieces as well.

In the meantime, the Wuhan foundry resumed operations in April, and the mill castings were successfully shipped to the United States. The Vulcan Machine team is currently in the beta phase and expects to begin production of CNC mills by early 2021.

Makerspaces: Beyond teaching

Vulcan Machine Co. co-founders attribute a great deal of their success to the support they received from James Madison University’s (JMU) makerspace, X-Labs. They met and started working together at X-Labs, and it helped them launch their company as well.

“We definitely would not be where we are today if not for the support of X-Labs and Nick Swayne, its founding director,” said Chris Ashley, co-founder, Vulcan Machine Co. “Nick is one of the most innovative and empowering leaders and faculty members that I’ve ever worked with.”

Like makerspaces at other colleges and universities across the country, X-Labs creates hands-on, immersive learning opportunities for students by using an active-learning classroom to bring together students from multiple disciplines to work collaboratively on real-world challenges and projects.

X-Labs is designed to go beyond teaching students about engineering or coding, although it does have laser cutters, 3D printers, machining equipment, and other equipment. It also has relatively advanced communications equipment such as on-demand videoconferencing to enable students to easily connect to and collaborate with outside experts and alumni on their projects.

In recent years, X-Labs projects have included technical challenges in the areas of augmented reality, autonomous vehicles, blockchain, the internet of things, and medical innovations. Students from more than 55 majors, faculty teams from more than 10 departments, JMU alumni, and dozens of private sector and non-profit organizations have worked on X-Labs projects including BAE Systems, AT&T, Compass, Smithsonian Conservation Biology Institute, and cybersecurity firm Endgame.