“Inspiring the Extraordinary” is the theme for IMTS 2024 – The International Manufacturing Technology Show, taking place Sept. 9-14 at McCormick Place in Chicago, Illinois. Plans are underway for the world’s premier industry event, and people are thrilled about new technologies enabling manufacturers to be more innovative, productive, and profitable. The industry has witnessed remarkable advancements empowering manufacturers to think differently and create unprecedented solutions.

“One year out from IMTS 2024 is a good time to assess efficiency, set new goals, conduct technology research, and plan equipment acquisition,” says Kevin Wigington, chairman of the AMT Show Committee and general manager for Select Production Technologies, a provider of CNC machine tools for high-volume production of complex parts. As examples of manufacturing efficiency, Wigington cites turning centers that combine multiple operations (e.g., milling, hobbing, and grinding) in one machine, pallet conveyors, and systems that use a sub-spindle or multiple axes to machine parts in a single setup to reduce cycle time and minimize geometric and shape defects.

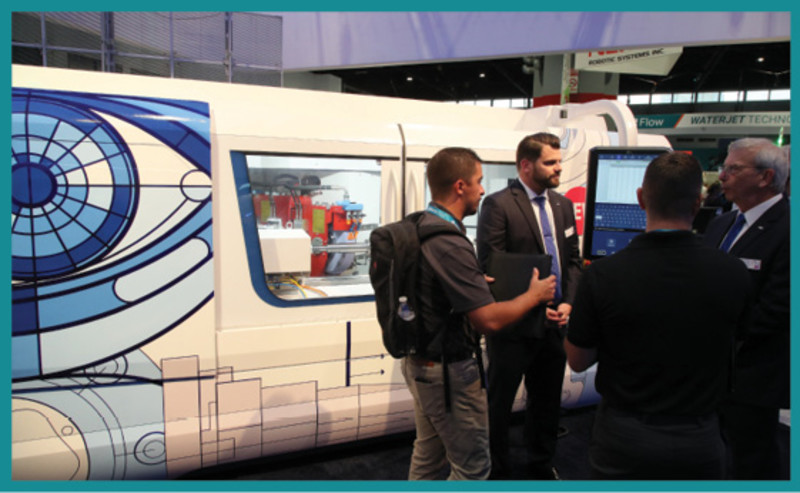

United Grinding representatives discuss the STUDER S31 with the CORE (Customer-Oriented Revolution) operating panel, shown at IMTS 2022.

“Complement your machine with any technology that can boost unattended run-time,” adds Markus Stolmar, president and CEO of United Grinding North America. “For example, combination machining centers, tool measuring machines, and grinders now feature integrated tool changers, metrology equipment, and the ability to laser scan a tool or part to generate a 3D model.” Stolmar notes that machine manufacturers are offering compact, more affordable machines so that job shops can move work in-house. “IMTS showcases the full spectrum of cutting-edge technologies that lead to business growth,” he says.

As part of moving work in-house, such as by adding a smaller machining or turning center, companies need to research cutting tools that match their needs, which often require a broader application range. For example, Kennametal’s KCP25C, a new steel turning grade, is designed to machine steels and PH stainless steels.

“The new grade, depending on application, has been used in both P10 and P40 turning applications,” says Scott Etling, vice president of global product management at Kennametal. “New medium versatile and finishing versatile geometries also provide customers with the flexibility to take light to heavy depths of cuts. The new geometries are engineered to lower cutting forces for smaller machines in addition to offering excellent chip control when needed.”

Melanie Lang, co-founder and CEO of Formalloy Technologies, believes the trend of adding AM equipment to move work in-house is growing. “The last few years opened our eyes to the instabilities in our supply chain,” says Lang, whose company provides directed energy deposition (DED) AM systems. “We can’t take delivery times for granted. Fortunately, we can apply technology to solve those problems.”

As examples, consider large-scale metal additive technologies to replace forgings, castings, and tooling, which typically come from overseas and with long lead times. Other applications include out-of-date parts (notably for defense systems) or remote locations (e.g., military bases).

“When you deploy additive, typically you can do most work on a single setup on a single machine without stocking a lot of extra parts,” adds Glynn Fletcher, president of EOS North America, the leading provider of laser powder bed fusion technology. “You can have a small installation very close to where you need it.”

EOS at IMTS 2022 showcasing the AMCM M 290-2 1kW system and Hyperganic aerospike rocket engine made with EOS technology and material.

“The manufacturing and warehousing sectors remain optimistic, prompting company leaders to look at the big picture,” says Doug Burnside, vice president for Yaskawa Motoman. “From reshoring initiatives and workspace optimization to production capacity and workforce shortages, multiple issues are often at play when companies are looking to invest in automation technology.”

Some of those technologies include robots that combine artificial intelligence deep-learning software with 3D cameras to create human-like vision and achieve pick rates of 1,200 to 1,700 per hour for a wide range of objects. Extremely fast and intelligent robots help companies meet order fulfillment demands, a trend driven by e-commerce sales, which grew to $272.6 billion in the first quarter of 2023, according to the U.S. Census Bureau.

“Capital expense items have longer purchase cycles, so start evaluating solutions before the need becomes critical,” concludes Wigington.

Register to attend IMTS 2024 at IMTS.com/Register and be inspired to create the extraordinary.

To read the rest of the Energy Issue of MT Magazine, click here.