Release date: 16 October 2020

Episode 35: Ben and Steve start by discussing the latest consumer electronics. Steve talks about the advanced manufacturing going into the newest American made hypercar. Ben describes digital twin readiness. Stephen brings up the rights of… robots? Ben introduces two additive techniques used in a single machine. Steve talks about the latest CAM software geared for modern mobile devices and digital twins. Ben gets lost in a minefield.

- https://www.youtube.com/watch?v=VdG4gUTowXc&feature=youtu.be

- https://www.amtnews.org/post/how-to-build-a-digital-twin

- https://thenationonlineng.net/rights-of-robots-in-emerging-technology-environment/

- https://www.amtnews.org/post/lmd-wp-a-synergy-between-wire-ded-and-powder-ded-on-a-single-machine

Subscribe to the Weekly Newsletter https://www.amtnews.org/subscribe

Amateur Machinist Blog https://swarfysteve.blogspot.com/

Music provided by www.freestockmusic.com

Transcript:

Benjamin Moses: Hello everybody, and welcome to the Tech Trends Podcast where we discuss the latest Manufacturing Technology research and news. I'm Benjamin Moses, the Director of Manufacturing Technology, and I'm here with?

Stephen LaMarca: Stephen LaMarca, AMT's Manufacturing Technology analyst.

Benjamin Moses: Steve how you doing today? How was your week?

Stephen LaMarca: Doing awesome, a bit tired today. As you know we had a fun night last night with our happy hour.

Benjamin Moses: That's true, yap.

Stephen LaMarca: Yeah. We were saying before we started the recording here, it was a shame we didn't record it last night because, even though we didn't have that many participants, barely any, actually. But it was a good conversation between you and I, and Will, and I feel it would have been solid content for the podcast but-

Benjamin Moses: Yeah. The audience missed out, we talked about subtractive manufacturing and some different materials that we cut our teeth on, and-

Stephen LaMarca: Oh, yeah.

Benjamin Moses: I didn't get into why or how many machines I've crashed in the past. Maybe i will save that for another happy hour.

Stephen LaMarca: Yeah, definitely save it for another happy hour. That's my favorite question to ask people.

Benjamin Moses: I mean, or what are they crashing into.

Stephen LaMarca: Yeah. Tell me about your first machine tool crash.

Benjamin Moses: Yeah.

Stephen LaMarca: People love talking about those, their first crash.

Benjamin Moses: There's some interesting things that are happening now in the consumer market, before we get into some Manufacturing Tech. The first one is phones on top of phones coming out.

Stephen LaMarca: Phones on top of phones, I think the most recent shenanigans that I've heard is, first off, most of us are still in the middle of this pandemic. A lot of people are still working from home. More and more people are being led out of their house lately, it won't get into whether it's the right call or not, but there's definitely more people out and about now-

Benjamin Moses: Sure.

Stephen LaMarca: ... even though we're still technically in a pandemic. But for the most part, a lot of people are still working from home, a lot of people are still keeping their distance. And especially people like you and I who are still working from home, no need to upgrade my phone because number one, Ben and I are both on Google Pixel 2s, even though the five is about to drop. The Pixel 2 processing speed wise, and quality of your pictures, and quality of the screen is still so high up there, that there's really no point to upgrade other than battery life. That being said, talking about battery life, there's no point in getting a new battery for your phone because that's one of the main reasons for upgrading a phone, it's time to get a new battery, because either the old one's shot, or its battery technology advances. Sadly, battery technology doesn't advance enough to keep up with the computing power that goes into modern phones, and the resolution of the screens that goes into modern phones and whatnot. But regardless, batteries deteriorate with age, and not just to lose their charge. And that's the primary reason a lot of people I would think, upgrade their phone.

Benjamin Moses: Right.

Stephen LaMarca: No sense in upgrading your phone to replace the battery if you're constantly sitting near a charger all day.

Benjamin Moses: That's right. And it's funny, I was going ask, a lot of our staff lives in apartments near the facility or in the city. And if you're in a small apartment, I wonder if you actually disconnect your phone from the charger?

Stephen LaMarca: I do.

Benjamin Moses: Do you? Okay.

Stephen LaMarca: In fact, I actually forget to plug it back in.

Benjamin Moses: Oh, do you really?

Stephen LaMarca: Enough. But I'm around so many other mobile devices that the battery actually wears away slower.

Benjamin Moses: Yeah. And I noticed that since you're on Wi-Fi more, it feels like it's burning, or it uses the power battery less than on a-

Stephen LaMarca: A solid Wi-Fi connection helps as opposed to jumping from cell tower to cell tower.

Benjamin Moses: Yeah. I like to stretch my phones out as long as I can.

Stephen LaMarca: For sure. And I think COVID has made that really easy. But then, we talking about that. Apple has the audacity to come out with a new phone.

Benjamin Moses: Sure.

Stephen LaMarca: And they even doubled down in that Apple's new iPhone 12, doesn't come with earbuds which isn't a big deal. They haven't come with earbuds for a while. They don't even come with a headphone jack anymore. I mean, forget it, why would you even expect that. The new 12 is not coming with a charger. And now of course, Apple is going to say that the new 12 isn't coming with a charger, so they can put it in a smaller box to reduce packaging waste, and so they can reduce the amount of chargers going in circulation to prevent electronics waste.

Benjamin Moses: Yeah.

Stephen LaMarca: It's like, if you really wanted to prevent electronics waste, you wouldn't come out with a new phone-

Benjamin Moses: The incremental change-

Stephen LaMarca: ... because you know previous phone which came out three months ago, is still relevant and good enough.

Benjamin Moses: That's right.

Stephen LaMarca: Clearly, including the charger is a money saving technique, a cost cutting technique that will not reflect upon the consumer.

Benjamin Moses: If anything, the phone will get more expensive.

Stephen LaMarca: Yeah, it is getting more expensive and you get less.

Benjamin Moses: Get less.

Stephen LaMarca: It's the, I mean, don't get me wrong, Porsche has been doing that for years and it's working with them. You could get a 911 GT3, or you could spend another hundred thousand dollars and get the 911 GT3 RS.

Benjamin Moses: Yeah.

Stephen LaMarca: And it's lighter weight. But how do they make it lighter weight? You don't get air conditioning and you don't get a radio. You don't even get door panels.

Benjamin Moses: Oh, they take off the door cards.

Stephen LaMarca: Yeah, they take off the door cards. Instead, you have a fabric pull tab to open the door, you don't even get a door handle.

Benjamin Moses: That's awesome. What is your signal to when you decide to upgrade your phone?

Stephen LaMarca: It's usually the battery-

Benjamin Moses: The battery is just completely gone?

Stephen LaMarca: Yeah. And when I do get out of the apartment, I do notice that my battery does not last as long, the battery life has definitely deteriorated a whole lot because, I do notice that, you open up a power hog app like Snapchat or something like that.

Benjamin Moses: Sure.

Stephen LaMarca: If you have like 17% battery left, on an Android at least, especially an older generation Android like a Pixel 2, if you have 17% battery left and you open Snapchat, there is a good chance your phone will shut off.

Benjamin Moses: Zip, done.

Stephen LaMarca: Yeah.

Benjamin Moses: That's awesome.

Stephen LaMarca: But other than that, the processing power of the Pixel 2 is incredible. It's insane.

Benjamin Moses: I was trying to do a quick search on, it was the first smartphone that I bought. I feel it was 2005, a few years before the iPhones came out.

Stephen LaMarca: Yeah.

Benjamin Moses: The Windows based phone with a slide out keyboard. I think it was a HTC model, but it was fairly thick. It was really thick, but it was a decent size.

Stephen LaMarca: Like the G1?

Benjamin Moses: It might have been, I don't remember the name.

Stephen LaMarca: The HTC was like the hardcore persons phone. A lot of people had it. It was separated down the middle between either you got an Apple iPhone, or he got the Motorola Droid.

Benjamin Moses: Yeah.

Stephen LaMarca: But there were a few hardware enthusiasts that were like, "No, you want the HTC G1 or something like that." Because I remember my first smartphone was the HTC G2 T-Mobile, that was a great phone. It had a swing out keyboard. It was like-

Benjamin Moses: Yeah.

Stephen LaMarca: That was a sick phone.

Benjamin Moses: And the struggle I have right now with my Pixel 2 is that, the phone that I had in 2005 does exactly what I want it to do today. There's a nice benefits of a bigger screen. I really like a really big screen, that's that's one change. But in all the progress on processing power on a phone, RAM, storage you should debate because they had expandable storage back then. But I don't need that powerful a phone. I mean, I do games once in a while, but likely you said, since I'm home all day I could just fire my computer and play games on that for a hot second and then jump back to work. But-

Stephen LaMarca: Yeah. I love the Pixel 1.

Benjamin Moses: Yeah.

Stephen LaMarca: And you had a Pixel one as well, right?

Benjamin Moses: I did. Yeah.

Stephen LaMarca: I loved my Pixel 1, but I was cheap and didn't go with the increased storage capacity, and I regretted that. So, when I bought the Pixel 2, I made sure to get the much larger, I think it was 128 gig storage capacity on the Pixel 2. And then as it turns out, once I got the Pixel 2 up and running and had all the settings the way I liked it, Google now had the cloud. And internal storage capacity didn't matter.

Benjamin Moses: Yeah.

Stephen LaMarca: Didn't matter at all.

Benjamin Moses: You got outplayed.

Stephen LaMarca: Yeah, I think totally played me. But I still love that phone and I'm still using it. So, who played who?

Benjamin Moses: And it's funny because-

Stephen LaMarca: No, I still got played.

Benjamin Moses: ... I talk about how I'm resistant to change on a phone, but the next one I'm really interested by is the Samsung Fold.

Stephen LaMarca: Yeah. Okay.

Benjamin Moses: It's the world's biggest phone. It's massive.

Stephen LaMarca: So, you're really going to invest in a folding screen?

Benjamin Moses: So, it's really expensive for me right now, if they get to like a third generation, I may buy the second generation. It's too expensive for me now. So, I had a Galaxy Note back in the day, and I just love the massive screen, you could do so much on there.

Stephen LaMarca: Got you.

Benjamin Moses: If they included the pen on the Fold, I will be tempted to buy right now.

Stephen LaMarca: So, I'm like the opposite of you.

Benjamin Moses: You like smaller?

Stephen LaMarca: I think phones are too big now.

Benjamin Moses: Yeah.

Stephen LaMarca: Yeah, I want all the processing power, I want all the RAM, I want the awesome camera. Don't need a physical keyboard, that was something that played a lot of people, that some people I know were like, "I need a phone with a physical keyboard, that's why I didn't go with the iPhone." And then it's like, "Nobody has a keyboard anymore."

Benjamin Moses: All right. We also talked about consumer goods and true bottlenecks. You and I have been talking about AMD and Nvidia releasing a bunch of new products, and-

Stephen LaMarca: We haven't been able to shut up about AMD and Nvidia's latest gen GPUs.

Benjamin Moses: Right.

Stephen LaMarca: And there's a lot of buzz about, well, you can't even utilize the Nvidia RTX 30 series if you don't have one of the latest motherboards. Because the Nvidia RTX 30 series is best utilized, or you get maximum utilization out of it if you have PCIe Gen four, and PCIe Gen 4 motherboards came out this year.

Benjamin Moses: Right.

Stephen LaMarca: So, if you have a two year old motherboard, and you're thinking, oh, man, I'm going to get ahead of everybody, it was smart of me to skip a generation in graphics cards. No, it wasn't. You need to buy a whole new computer now. Because your motherboard is going to bottleneck it. Marketing has played me so well, because there've been a few times, a handful of times within the past month where I've been thinking about, dude, I'm going to get the latest RTX 3070 when it comes out.

Benjamin Moses: Yeah.

Stephen LaMarca: I'm like, the RTX 3070 is the latest GPU for me. And I keep forgetting that I practiced, I did a little bit of tinkering and overclocking with my RTX 2070 Super that I have now. And that card is overpowered for my setup. It's not the bottleneck at all. There's no point in upgrading that when everything else is holding it back right now.

Benjamin Moses: That is a very good point. All the reviews, everything that I've read so far that, if you're looking at stuff to buy right now, which is quite the funny dilemma because the companies have supply chain issues or supply issues, because apparently so many people are buying it. But right now, most games are not running 100% of the GPU utilization, it's another bottleneck, is either CPU utilization or some other bottleneck in the system. So, upgrading right now, I mean, it doesn't make any sense. What's boggles my mind, why they're running out of video cards, but you just stuck at the hype of it, right? One, the graphics cards look really cool, so, a lot of people are like, "Uh, this is a shiny new object. Let me buy this right now.

Stephen LaMarca: Everybody loves new metal.

Benjamin Moses: And I'm so happy that I started doing more research recently, because next year, I'm going to do an upgrade. But I'm so happy that I've been able to stretch my fourth gen CPU.

Stephen LaMarca: Dude, that's impressive. No joke. I keep telling people, whether it's like the people I game with at night, or Shawn in IT that, "Ben's on a fourth gen Intel i7." Would you say it's the bottleneck of your system?

Benjamin Moses: Oh, yeah, definitely. So, I've done some benchmarking.

Stephen LaMarca: Okay.

Benjamin Moses: So, I recently, as in couple weeks ago, upgraded my monitor. So, I have a 4K monitor that could hold 60 hertz. And it has FreeSync built in so it can run lower, and much the same frame rates coming out of the video card.

Stephen LaMarca: That's sick.

Benjamin Moses: Yeah. So, I'm really happy with that. And I'm really happy with 60 hertz, I don't need anything more than that. But with the current system I have, I did upgrade the graphics card two years ago to a GTX 1080.

Stephen LaMarca: Grey card.

Benjamin Moses: Grey card. But the CPU is now the bottleneck. So, I'm running 110% CPU max at 99 degrees just before thermal throttling. And the GPU is at like 25% low.

Stephen LaMarca: Yeah, that's a two generation old GPU. Because I think the last time we were talking when we were blabbing about GPUs, I mentioned that, supposedly, the RTX 20 series, with the Nvidia's Turing architecture, was the first ray tracing capable GPU.

Benjamin Moses: Right.

Stephen LaMarca: And then they quietly released like a year later, some driver updates for the GTX 10 series.

Benjamin Moses: That's right.

Stephen LaMarca: I was like, "Oh, by the way, the GTX 10 series, that's also capable of ray tracing."

Benjamin Moses: Yap. Now, the last thing I want to talk about, so I've gotten into RC cars-

Stephen LaMarca: Dude, you are such children.

Benjamin Moses: I'm back to it man. I'm such a child.

Stephen LaMarca: I love it.

Benjamin Moses: So, last year I did a test, I think like a $150 RC car is the best entry into RC cars. It's a good, ready to run RC car. So, it usually comes with-

Stephen LaMarca: Out of the box.

Benjamin Moses: Out the box. You just pick it up, you may have to charge the batteries, it may even come with a charger, it comes with a remote.

Stephen LaMarca: Okay, this is electric.

Benjamin Moses: Yeah, it's all electric. Oh, yeah, I'm not going nitro or gas, that's for RC nerds, those guys are-

Stephen LaMarca: I think it's sick.

Benjamin Moses: So, I got in that last year, just to try it out to see if I'm enthusiastic about getting into it and how often I'll use it. So, when I first bought it, it was like every day was an off road one, I went into my backyard, I couldn't get the front yard, I could just charge it or charge it the night before and it'd be ready to run. Just so everyone knows how powerful it is, the battery packs on it, it's a two pack, but both of them combined a roughly four AA batteries. So, that's around the size that you would put into the car, and that gives you a scale of the motor, right?

Stephen LaMarca: Yeah.

Benjamin Moses: So, it's a maybe 12 inch long RC car. And I use it quite a bit. Actually I use it so much, I think I broke the front, or I broke the center differential. So, it was all wheel drive, now it's front wheel drive biased. And it doesn't do too well on the road because it just spins the front wheels. So, I think it's on its way out and I have beat the hell out of that car.

Stephen LaMarca: That's interesting. Front wheel drive.

Benjamin Moses: A front wheel drive off road car.

Stephen LaMarca: Wow.

Benjamin Moses: It's not that [inaudible 00:16:48].

Stephen LaMarca: I can't even fathom a front wheel drive RC car.

Benjamin Moses: Yeah.

Stephen LaMarca: You're growing up. First, of growing up, $40 got you a premium RC car, right $20 got you one that was excellent and good enough. And Ben's coming out swinging, "Best RC cars 150 bucks out the box. 90 mile an hour top speed, 60 mile an hour on the road."

Benjamin Moses: So, I've had that $150 car about a year and I beat it up, it's on way out. Their replace and parts are plenty, so you can find it.

Stephen LaMarca: That's cool.

Benjamin Moses: That's the best part about that specific car. But I'd used it so much I was like, "Okay, I think I want to get a car that can do a little bit more on road." So, I looked around and I found a one Bell just being released, and I bought it, and for scale the battery pack's on this. So, it's two battery packs also, but it's roughly 20 AA batteries. So, just for a matter of scale of how big it is. The car itself is 27 inches long by 12 inches wide. It's one-seventh scale car labeled, so, one-seventh, one-eighth, one-sixth among there. But right out of the box on the road, with the gearing that is set too and the battery packs that I bought with it, go 60 miles an hour on the road. So, I've in my neighborhood that has a speed limit of 25 miles an hour zipping past my house at 60 miles an hour. This thing is outrageous. I'm blown away by how powerful this thing is. And it comes with the gear that you can change out on the motor, that'll crank it up to close to 90 miles an hour.

Stephen LaMarca: It's absurd. A little bit slower acceleration but a higher top speed.

Benjamin Moses: It just blows my mind every time I fire this car up which is almost every day.

Stephen LaMarca: That's sick that you can adjust or change the final drive ratio.

Benjamin Moses: Yeah, that's amazing. It's such a good experience. Anyone that's on the fence about getting the RC cars, get of that.

Stephen LaMarca: That's as good missile on wheel, it's not an RC car.

Benjamin Moses: I took it to a park nearby, and I was driving in parking lot there. And I took it all the way in the parking lot and I was driving back, and I didn't realize how long the braking distance was. So, I got on the brakes and it was way too short in a slit underneath my car. It was in the middle of my car. It's a BMW 1 series, so slid underneath my car and this low enough that it got wedged there.

Stephen LaMarca: Oh no.

Benjamin Moses: I broke some of the front fairings, I just obliterated the top of the car-

Stephen LaMarca: Hope it didn't get pinned underneath like the catalytic converter or something like that and catch fire.

Benjamin Moses: No. [crosstalk 00:19:13].

Stephen LaMarca: That would just been lovely. Well, how did you explain that one to your insurance?

Benjamin Moses: It's so much fun.

Stephen LaMarca: Dude, you should definitely bring that to the AMT Halloween that we are having on the rooftop of the garage outdoors so we can responsibly socially distance.

Benjamin Moses: Yeah, if I come.

Stephen LaMarca: It's going be fun.

Benjamin Moses: Yeah.

Stephen LaMarca: You should dress your RC car up like a spider and just chase people with it.

Benjamin Moses: I was getting some articles speaking of cars. The good thing you got a good one on-

Stephen LaMarca: Oh, yeah. Well, so a while back you actually mentioned that American supercar company. Well, this pretty wealthy dude, who decides he wants to make this fancy hypercar.

Benjamin Moses: Sure.

Stephen LaMarca: And when we first talked about him months ago, it seemed like he was really seriously. He bought a advanced manufacturing facility to produce his dream car. And fast forward to now, well, yesterday actually, Donut Media, one of my favorite YouTube channels, that's definitely gearhead oriented, and even though they do a great job on educating and explaining some of the latest technologies, that channel is typically geared to be entertaining and cater to not necessarily the ivory tower academics. At the end of the day, it's a car channel for gearheads.

Benjamin Moses: Right. It's entertainment.

Stephen LaMarca: But their video that they released yesterday, is on the Czingr, spelled C-Z-I-N-G-R 21C, which means 21st century. And they're just talking about the title of the video, is AI Designed this Car. And I was actually really impressed by Donut Media because they got into the weeds of actual advanced manufacturing techniques, and not even advanced manufacturing techniques, but they got into transformative technologies in our industry today, by saying that, "Ai designed this car, and the car is mostly..." I don't want to throw a percentage out there but, "... the car's mostly additively manufactured. And they even said additive manufacturing, they didn't throw out 3D printing. They actually used the term additive manufacturing, which I give a kudos to anybody who says that over 3D printing. Just because I think that's an overplayed, not vaporware, but it's just lowbrow consumer term.

Benjamin Moses: Sure.

Stephen LaMarca: And if you want to be taken seriously say additive manufacturing, but if you want to get noticed you say 3D printing, but whatever. They say AI designed this car and I'm really hoping AI plus additive to me sounds like generative design, are they going to throw that? And they didn't say anything about it, but it doesn't matter. They did enough. They did my heart well to talk about that. But it's just cool that they brought up with that car again, and it seems like this guy with his advanced manufacturing facility is really serious about making his dream car. If he only makes one and it's just for himself with like four US government road test models to be crashed, more power to him. There's no better way to say you have a one off car to flex your massive amounts of money, your three commas in your bank account, than creating a one off car that you made, that you bought a advanced manufacturing facility just to make one car for you, that's a flex man, nobody else can do that.

Benjamin Moses: It's funny that when you start something from new, when you don't bring any previous history, there's some risk in that. But being able to-

Stephen LaMarca: The guy is like a bicyclist.

Benjamin Moses: Yeah. But when you're able to start a manufacturing process or facility from brand new, you can implement some really interesting technology. So, like bringing all the additive processes-

Stephen LaMarca: That's a good point, yeah.

Benjamin Moses: ... and being able to use AI for their designs, for their processes.

Stephen LaMarca: Yeah, you don't have to worry about the whole implementation into your current production line. And it's, dare I say, legacy manufacturing technologies are a bottleneck to transformative technologies-

Benjamin Moses: Yeah, it could be.

Stephen LaMarca: ... but we don't want to hurt any feelings.

Benjamin Moses: No. And to be fair, I mean, I think having money as a buffer for time helps too. So, if you're in different environment where you had a firm deadline, you'd go with more proven technologies, more proven processes, starting something from scratch you have to verify, validate the design every step of the way, and that's time consuming. So, having that buffers helps a lot. It's awesome. Yeah, I'm happy to see that they're getting into some more technical content, and there's a good stuff for them.

Stephen LaMarca: But I noticed for sure.

Benjamin Moses: The next article I have is about the digital twin. And it's interesting article that gets into some of the three main areas that companies can benefit from the digital twin. So, first off, the digital twin is just a virtual representation of a real object, right? So, you could say the 3D CAD model made of this coffee cup is a digital twin, right?

Stephen LaMarca: Right. You could.

Benjamin Moses: You could, right? We'll say that's the most foundational level of saying-

Stephen LaMarca: It's not wrong.

Benjamin Moses: Yeah, correct.

Stephen LaMarca: Let's put it that way.

Benjamin Moses: Now, I think in today's environment, what we're doing is matching up how the object behaves in the real world, with how it's represented in the virtual world. So, now the adding behavior or data to represent if it's moving, or if it's collecting data or if it's transmitting if it's working. And that's more of a current definition of the digital twin, right? So, you have your, or call it a car. I have a digital twin of a car, I have the 3D model, but now I've got ematic data to how that car is behaving in real life. So, that's all we're looking at for today.

And it goes over a couple of things, one is the barrier. So, they're talking about for manufacturing, how do you represent a digital twin of your either process, or the part running through your process. And the key takeaway is that you want it to represent your factory, to improve your asset management, understand your maintenance for productivity. And in the end, you want to get your product to your customer on time and on budget. So, they're saying that the digital twin can help you get to that state. It's not the only way, but it's one way.

Stephen LaMarca: Sure.

Benjamin Moses: The first thing they talked about are barriers. Like you mentioned, if you have a company that's a little bit with dated IT infrastructure, that's probably your biggest hurdle right now is that, updating your IT infrastructure to support the amount of data that you have to transmit and collect, is probably your first hurdle.

Stephen LaMarca: Yeah, absolutely. If doesn't mean you immediately have to adopt 5G.

Benjamin Moses: That's right. Just upgrading your switches, making sure you have the right Cat6 cable, just making sure you can get data from one place to another efficiently, and you have data to stream YouTube videos while you're launch. That's the key, is making sure your machine data is not clogging your YouTube data bandwidth. But the first one is cost to digitize the process. So, you've got the IT infrastructure, and then the article talks about collection, what data should be included into the digital model? So, if you're creating it, and then how you're representing it in production, what data did you want to include in the representation. So, if you have a 5-axis mill, do you need pressures and temperatures? Do you need speeds and feeds, there's a whole ton of data that you will want to understand. And in the end you have to figure out, what question are you going to answer? Does the data help answer? Right?

Stephen LaMarca: Right.

Benjamin Moses: If you start saying, "Give me everything." That is not a good answer-

Stephen LaMarca: No, it's terrible.

Benjamin Moses: ... that will you thousands and thousands of tags, megahertz of data frequency constantly updating into a database which will probably get overloaded and you're screwed. So, the key thing is defining what data you're going to put into your model in the beginning, and what data are you going to collect-

Stephen LaMarca: I think you just said that, what I was going to say, but more specifically, what is your problem that you're trying to solve? What are you going for? And then you find out specifically, let's say that problem you're trying to solve has an equation, you want to find out what variables are in that equation, so those variables are the data you want to collect.

Benjamin Moses: Yeah.

Stephen LaMarca: There is such thing as too much data, there's absolutely so much such thing as too much data.

Benjamin Moses: Yap. And last thing they talk about is security. So, now you've defined IT infrastructure, you're collecting data, you're transmitting data, but now they're really concerned about security. And in the past year or so, there's been a lot of ransomware, there's a lot of breaches. So, cyber security is a big thing that can be implemented in the early design phase of your factory. So, as you're developing architecture of, these are my machines, these are data things that we want to tag or collect in the future. Now, as part of the design processes, how do we want to transmit that data safely and securely? And how do you store and reduce risk of breaches once a twin is implemented? So, there's the risk of breaches or the risk of block data in today's world. So, the article has a pretty good overview of some key factors to help think about if you want to get some type of digital twin as your factory.

Stephen LaMarca: Yeah, it's always a good idea to read up on cybersecurity in general.

Benjamin Moses: Absolutely. You've got an article on robots? I hear that robots are getting touchy.

Stephen LaMarca: Oh yeah. Dude. Okay. So, Tech Trends has found this awesome article from, the website is called thenationonlineng.net. And it's a Nigerian news website.

Benjamin Moses: Okay.

Stephen LaMarca: And I've read a handful of articles by this author before. This gentleman's very well versed in law, and in emerging technology. Especially, funny enough manufacturing technology, I don't typically think of manufacturing technology and law in the same profession for some people, but this dude in Nigeria has got it. And I'm reading this article, and it is absolutely not written, like your typical journalist publication. It's written like a legal document or even a political proposal. The title is, Rights of Robots in Emerging Technology Environment.

Benjamin Moses: Interesting.

Stephen LaMarca: And this was published yesterday. And it's a really cool concept. And I'm getting halfway through it, and I'm realizing, dude, this guy is serious, this isn't just some journalistic BS. This guy is talking about things that we need to think about as a human race with the upcoming, the adoption and implementation of all these robots around the world, we need to start thinking about the rights of robots before AI and robots rise up and have their own civil rights movement against humans. That's quite literally what this article is about, and it's serious, this isn't some Terminator Spoof, even though my mind went to that immediately. And I think I definitely threw it in this week's Tech report.

Benjamin Moses: Yeah.

Stephen LaMarca: And it's a good read, I highly recommend it, and it's definitely something to think about and something that should be thought about.

Benjamin Moses: Yeah. And I think it's a more practical approach to the concept of rights for robots, because as soon as you mentioned that, then you'll see the picture of a humanoid robot, talking and behaving, that's not what the article is talking about. Is talking about different types of robots use in other industrial applications, right?

Stephen LaMarca: Yeah, in the workplace.

Benjamin Moses: In the workplace. Yeah. So, if you've got autonomous ground vehicles that could be considered robots, you've got single arm robots, anything that's acting on your behalf, is considered a robot.

Stephen LaMarca: An AI software even-

Benjamin Moses: Yeah, absolutely.

Stephen LaMarca: ... whether it's for eCommerce or retail. I joked saying that, the future is going to favor those of us who showed mechanical sympathy.

Benjamin Moses: For sure.

Stephen LaMarca: So, if you were somebody who didn't throw phones, you're probably in good shape.

Benjamin Moses: I might get in trouble for throwing my old Super Nintendo Controller on the ground.

Stephen LaMarca: Everybody's snapped a controller growing up.

Benjamin Moses: Yap. The next article I've is about multi-material for additive.

Stephen LaMarca: Oh, cool.

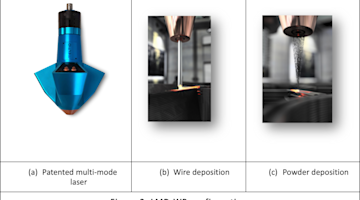

Benjamin Moses: So, an additive machine or 3D printer, it can process different materials. So, if I've got a copper, you could theoretically switch it out to aluminum, if you got to get rid of... but it's all powdered. Or you could have a different machine that does wire feed. So, you're feeding similar to like welding wire, and melting and growing your part that way. This machine that we ran across the other day, it actually has both capability built into it. So, you could feed wire, or you could feed powder, or both at the same time theoretically, and it's fairly interesting. So, I just wanted to talk about some of the benefits of either or, right? So, one of the drawbacks of additive, especially powder bed, or powder fed machines, it gets really good resolution, especially powder bed, they're very accurate. The step over is very small, surface finishes are pretty good. But the time to grow that part, or the volumetric growth rate are fairly slow compared to other processes. That's where the drawback of powder fed machines are. And that's where wire feed machines come into play, where you have a larger volume of wire being shoved into the melt puddle and growing apart that way.

Stephen LaMarca: Absolutely.

Benjamin Moses: But the drawback is lower resolution, you have a higher step over. So, it's a trade off. But it's interesting that you're able to combine both those capabilities in a single machine as opposed to try and get to different machines if you need to grow a bigger part or high resolution part.

Stephen LaMarca: Yeah. And firstly, that article because I read that as well, it was very well written and it was very good at getting the reader up to speed on the various things technologies that could be found in this single machine, and the intricacies of metal additive.

But I think what's really cool is, it was only a matter of time that a machine would come out like this. I don't think while it's great and it is innovative, I don't think it's that innovative, because... I don't mean to sound like I'm talking ill about it. Because this is absolutely necessary. It was a matter of time, this had to happen. A machine like this had to come out because you don't want to think about... Let's say you have a milling machine, like standard size milling machine. Does it make sense to buy a 5-axis milling machine that can only use a one-sixth inch ball end mill?

Benjamin Moses: Sure.

Stephen LaMarca: No, you want to be able to do a tool change from that to like a half inch flat end mill. Because there's not one size end mill to do it all. Sure. You could manufacture, you could cut machine apart with only a one-sixth or 130 second ball end mill-

Benjamin Moses: Well, it'll take a while.

Stephen LaMarca: .... an entire part, but man that would take for ever. And then it's like, why don't you just 3D print it because it would take just as long.

Benjamin Moses: Yeah, so you saying grata necessity or okay-

Stephen LaMarca: Yeah.

Benjamin Moses: Yeah. I'd do that. It's interesting. So, I just want to talk about the material form, so you can grow parts quicker, potentially. But also, Nelson said both of the materials go down the same central axis, and they get to the same laser source. You could alloy materials as you're growing the apart. So, you can have different wire and different powder, and as melting you creating your alloy as you're building apart. It was fairly fascinating. I've always been interested in bi metal parts, and I think there's a lot of opportunity. I think we've talked about that for knives in past episodes where-

Stephen LaMarca: Yeah, absolutely.

Benjamin Moses: ... you want a harder front edge, but maybe softer back end, or-

Stephen LaMarca: Yeah, you could keep the same alloy and not even change materials, but the process of printing would theoretically have allow you to vary the hardness of different layers.

Benjamin Moses: Yeah.

Stephen LaMarca: I think it would be really cool if, this is just random idea I thought of while we were talking about this. Really cool to see this multi use additive technology in a hybrid machine.

Benjamin Moses: Yeah.

Stephen LaMarca: And if the hybrid machine, when it did a subtractive pass with like an end mill or something like that, if the pass was optimized, so that the chips were of the right size, that the chips could then go through some recycling process and be reused as powder. That would be the ultimate way to save some material.

Benjamin Moses: And I was thinking about that also on a hybrid machine, I think the wire feed is the way to go, because you have the ability to machine off any low resolutionary that you want, so you could get away with a higher step over or higher thicker layers, if you're got a machine that edge anyway.

Stephen LaMarca: Are there hybrid machines that print and cut as they go?

Benjamin Moses: So, one of the drawbacks of additive is so much a welding process. So, if you're trying to grow apart on a previous layer, you need the cleanliness and rigor of a welding process, which means you can't have a coolant or debris or anything like that as you're welding.

Stephen LaMarca: Got you.

Benjamin Moses: Anything like that as you're welding, so yeah.

Stephen LaMarca: Okay. Maybe [inaudible 00:39:10].

Benjamin Moses: Maybe next year. You mentioned you have an article on CAM? It's been a while since we talked about some CAM software.

Stephen LaMarca: Dude, it has. Was i going to talk about CAM first or the NFL helmets?

Benjamin Moses: Either, well, why don't we do the CAM first.

Stephen LaMarca: Let's talk about CAM. Okay. I totally forgot our order.

Benjamin Moses: That's all right.

Stephen LaMarca: So, no joke, this engineering.com published this article today, a couple minutes ago. Which is great. By the way, engineering.com's articles I love because before you even start reading them, there's an option to listen to the article. So, if you don't want to read or if you're in the middle of doing something else, so that's awesome. Now, full disclosure, this article by engineering.com, as good as it is, it is a little bit advertising because they're really talking about Verisurf's new CAD CAM technology.

Benjamin Moses: Sure.

Stephen LaMarca: But I don't have a problem talking about them. For sure other companies are mentioned, just as much so. But anyway, Verisurf basically, they're pushing this new software, there's Verisurf 2020. And they list out four features, four really big features for this new version of their software, but two really caught my eye. And those two bullets being, updated metrology hardware support. And the second one being mobile companion apps for iOS and Android.

Benjamin Moses: Well, that's cool.

Stephen LaMarca: Lets talk about the first one though.

Benjamin Moses: Sure.

Stephen LaMarca: Updated metrology hardware support. This is CAD CAM software that is geared to fully utilize whatever inspection or probing metrology you have, and get that into your CAD design. So, what's really cool, they even talk about being able to use this software to control something like a CMM or a probe to enhance the quality and surface quality of a simple STL file of a part you have.

Benjamin Moses: Okay.

Stephen LaMarca: So, if you design a cup, or a really crude cup, and it's all polygonal and stuff like that, but you actually have the physical copy of the cup that you want to make, you can actually use a CMM to like measure the cup you want to make, and it will edit your crude design as you go.

Benjamin Moses: Wow, that's interesting.

Stephen LaMarca: And so, that first bullet point that I want to talk about, this new software by Verisurf is really optimizing... really geared towards the push for a digital twin.

Benjamin Moses: Right.

Stephen LaMarca: You can design something and then you can make it. And once you make it, it can scan what you've made, and then make your digital design more accurate based on the physical thing you just made.

Benjamin Moses: Yeah, that's impressive.

Stephen LaMarca: The other really cool thing that they started with in the article was my last point that I mentioned, their mobile companion apps for iOS and Android. More and more people these days are using smartwatches, whether it's an Apple Watch, or some Android smartwatch, or even, a lot of people don't even wear watches anymore, because, if you want to check the time you look at your phone. I think I'm one of the few Luddites that's still rocking a mechanical watch, but-

Benjamin Moses: I still enjoy wearing a watch.

Stephen LaMarca: Right. That weight on your wrist feels nice. But I take risks. The cool thing that they're showing off is, this software, you can also buy like this hardware that's optimized for Verisurf, and it's like a dongle almost, that you hold in your hand as like a technician or as an inspector, or as a machine tool operator, if you're meant to measure apart, like you put it on your part and you drag it across like you're scanning it, and it sends the data directly to your smartwatch or your mobile device, to show you what the measurement is.

Benjamin Moses: Wow.

Stephen LaMarca: So, you forget the pencil and paper and fiddling with calipers, as much as I love a good pair of Mitutoyo calipers, it's doing it for. Even though, I got to say, the most recent before we got locked out of the office, one of the things I did buy for the testbed was a really nice pair of Mitutoyo digital calipers, that are Bluetooth enabled. So, you can measure something and it sends the readout to your phone. This is like that button more real time, I guess.

Benjamin Moses: I really like manufacturing steps to just get rid of pencil and paper. So, being able to runtimes or data right off the machine. So, if you did any type of continuous improvement project, the first thing you did is baseline your data set. So, you would send an intern or your continuous improvement guy with a stopwatch, and notepad and a pencil, to go and stand in front of the machine for as long as it's running. So, it could be like an eight hour process. He's going to be there for eight hours collecting data.

Stephen LaMarca: Yeah.

Benjamin Moses: And I'm glad we don't have to do that anymore. And I'm glad we don't have to have someone just write down the measurements. I have it digitized to your device that you want. So, that's amazing.

Stephen LaMarca: UI and HMI, user interface and human machine interface is a real segment of the industry that doesn't get enough love because it's constantly being upgraded. And it's something that will never be put on the backburner shelves or anything like that. But it never gets the headlines. And this is cool that they're doing something like that.

Benjamin Moses: Awesome. Steve, the last article we want to talk about today is additive minefield. We went straight from loving additive and talking about minefields now.

Stephen LaMarca: Oh, man. They could have worded this like, threats of additive or weaknesses of additives or some pros and cons and focus on the cons. But they straight up one to area denial.

Benjamin Moses: Exactly. And the underline theme here is that these are problems that are beneath the surface, problems that you won't see if you're getting into it. All the stuff that we talked about that was the positive stuff of additive.

Stephen LaMarca: Yeah.

Benjamin Moses: Who's talking about the negative stuff? Who's saying the problems that of have industry, and this article talks about four of them. They have four themes... Oh sorry, three themes. One is business planning. The other one is design. And the third theme is post processing. So, the first landmine they talk about is having the right people and resources for collaboration. So, the big takeaway here is, as you get into it, it requires a certain amount of skill, it's not something maybe you can pick up right away, it's probably something that's developed over time. So, identifying the skill level for engineering, skill level for operations, skill level for maintenance, there's a bunch of different tiers that require a certain amount of skill to be productive and additive. And that's the first thing they talk about is, do you have the right people to move forward. And they'd also mentioned collaboration, so, working with another company or a university or school to make sure that the skill is available. The second one, and they talk about is, understanding the keys for your return on investment. So, how long will it take for you to get your return on investment? So, the article talks about the cost of actually building the part, and understanding how often you're going to have to build something to get a return on investment. So, I thought that was very interesting, and it's very applicable to most companies when they talk about new capital or new technologies that want to implement is, understanding the ways that the device can get a return on investment. And I think that's key to understanding that before getting into it. The last two, using conventional approaches for development of additive processes, is a big no. Additive is a new way of thinking, a new way of processing, a new way of designing a part.

Stephen LaMarca: Right.

Benjamin Moses: It's okay. So, if you've got a part and you've got to clean up the surface finish, if you got to drill a hole, if you have to remove it from your baseplate, yes, you are going to have to go back to traditional means, you have to go back to subtractive manufacturing or other processes that have been around for a while. But using traditional standards to design your additive part, is going to put you in such a small box that it's almost no benefit. So, I think the big takeaway here is you've got to open your horizons quite a bit more and decide to the original point of, do you have the resources and skill set in house to have that creativity for the growth?

Stephen LaMarca: Yeah.

Benjamin Moses: And the last part is pretty straightforward. If I grow the part, now I've got to post process it. You've got build up material, you've got to maintain your dimensional properties, you have dimensional stability, so there's a lot more that's going to occur to the part not just grow it, then I put it into my car, you've got to grow it, you're probably going maybe do some finishing, you could do some hipping, maybe some stress relieving, there's a lot of other things that-

Stephen LaMarca: You got to X-ray it, CT scan, make sure there's no gaps.

Benjamin Moses: Make sure the porosity is low, and you may have to do a batch test of material properties, you may have to grow coupon to have that destructively tested. And they do that for castings quite a bit. So, there's a lot of other hidden things in retrospect to using landmines is probably the correct term here.

Stephen LaMarca: I agree with that now. It's funny that I never thought about it, but obviously, additive in a lot of cases is very similar to casting as you just mentioned. And you and I being gearheads, we've swapped wheels on our cars before, and as anybody getting into cars can tell you that certainly looked at buying new wheels for their car, is, there's different types of manufacturing processes, to buy wheels. And you're thinking about things like lightweight and strength, but you're looking at your wallet, and you're also thinking about, well, what can I really afford? Yeah, I'd love to have three piece forged wheels, but I don't want to drop $3,000 on one wheel.

Benjamin Moses: Right.

Stephen LaMarca: But at the same time, you also don't want to just buy some wheels for good looks and find out they're cast out of Chinese pot metal in some sketchy factory, and you sheer all of your spokes. But I'm looking forward to... Earlier this year when HRE, the big wheel company that is more on that expensive side I mentioned. When they made that 3D printed wheel, thinking about it, 3D printing, additive manufacturing is closer to cast materials, cast metals, and what scares me about that is, HRE's additively produced a wheel. HRE is a forged wheel company, they make very nice expensive forged wheels, and now they have this three additive wheel that's probably in terms of strength and material integrity, closer to a cast wheel-

Benjamin Moses: Sure.

Stephen LaMarca: ... in that respect. So, it'll be interesting seeing that in the future is like, well, now you can choose between an additively produced wheel, or a cast wheel, a flow formed or-

Benjamin Moses: Another option to choose from.

Stephen LaMarca: Yeah. And then forged in mail.

Benjamin Moses: Yeah. And I think the current state for those type of parts is, they're more form than function. So, I think the functionality will start coming into play later. And the functionality in additive and automotive is definitely grown quite a bit, but for rims is definitely all about the look, so yeah. All right, that was a good episode Steve, where can they find more info about us?

Stephen LaMarca: Heck, yes. They can find out more about us at amtnews.org.

Benjamin Moses: Awesome.

Stephen LaMarca: Slash subscribe, please. I beg of you. We need to eat.

Benjamin Moses: Are we done?

Stephen LaMarca: Yeah.

Benjamin Moses: Bye everybody.