"I think that most readers fail to realize that today's science fiction is tomorrow's truth.”

– Hal McAllister, “The Monthly Ticket,” Thrilling Wonder Stories, April 1952

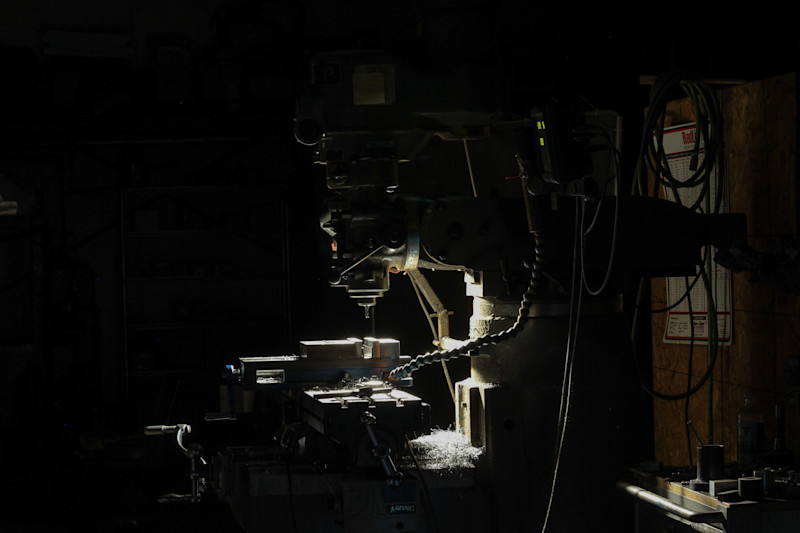

1. Think About Bridgeports!

Hardinge Inc., a global leader in advanced machine tools, has entered an asset purchase agreement with an affiliate of Centre Lane Partners for the sale of nearly all of Hardinge’s assets. As part of Hardinge’s chapter 11 proceedings and backed by $30 million in debtor-in-possession financing, this move will strengthen their financial foundation while maintaining global operations without disruption. The company aims to complete the sale within 50 days and will continue to serve its customers globally during this process.

2. A German Skills Gap Solutions

The United States needs a skilled workforce for successful reshoring, and Germany's apprenticeship model could be the solution! By implementing a system similar to Germany's dual education system, which combines apprenticeships and college, the United States can address its workforce shortage and improve global manufacturing competitiveness. Broad adoption of such programs can help balance trade deficits, promote income equality, and strengthen the economy. Wish my college advisor suggested it!

3. Llamas and GPUs Don't Mix

Meta's Llama 3 405B model training faced frequent GPU and HBM3 memory failures, with one failure every three hours in their 16,384 GPU cluster. Over 54 days, they recorded 419 unexpected failures. Despite this, Meta maintained over 90% effective training time. They used diagnostic tools like PyTorch’s NCCL flight recorder and managed environmental and power challenges effectively. The study suggests potential higher failure rates for larger GPU clusters.

4. 3D Printed Tooling for Cobots

Movie time! 3D printed tooling simplifies cobot integration in manufacturing by creating custom hardware like end effectors, grippers, jigs, and cable brackets. Cobots, unlike traditional robots, are easy to program and require minimal safety measures. The main integration challenge lies in how cobots interact with their environment. Universal Robots and EMI Corp. demonstrated the benefits of 3D printed tooling at NPE: The Plastics Show 2024.

4. Manufacturing Sennheiser Headphones

Let’s go on an unsolicited facility tour! An audio editor from Tom's Guide visited Sennheiser's factory in Tullamore, Ireland, to learn about and build HD 600 headphones. The blend of automation and manual assembly he experienced in producing these high-end headphones emphasized the precision and skill involved. Despite his expertise in evaluating audio products, he found assembling his HD 600 headphones challenging but gained a deeper appreciation for the craftsmanship behind Sennheiser's products.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/