“It's dangerous to go alone! Take this.”

– The Legend of Zelda (1986)

1. Adamantium but IRL

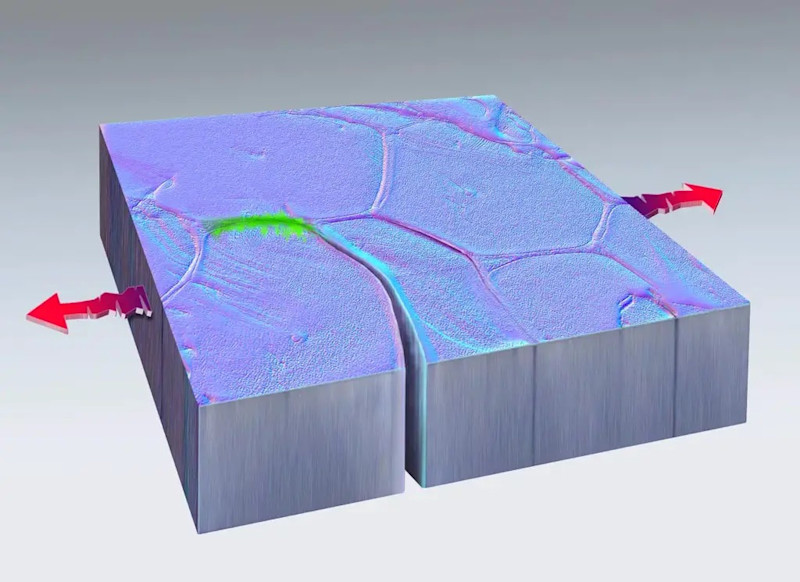

Made famous in Marvel Comics, the fictional metal alloy might not be so fictional anymore! Scientists at Sandia National Laboratories and Texas A&M University observed a microscopic crack in platinum that began to shrink and seemingly heal itself. The researchers were studying fatigue crack growth in nanocrystalline metals and witnessed the unexpected self-healing phenomenon. OK, so maybe not exactly comic-accurate, but it’s still pretty sick. Now they just need to alloy it with steel and Vibranium!

2. A Helping Hand

Robot arms are cool. Exoskeletons are even cooler! Sometimes, though, all you really need is a hand. Researchers from Queen Mary University, Imperial College London, and the University of Melbourne found that individuals can learn to use a supernumerary robotic arm effectively in just one hour. The study concluded that subjects with the robotic arm managed as well as those with a human partner. Wait… Programming a robot takes less time than what modern CAM software takes to turn a CAD file into G-code?

3. Generative Robots

The future looks promising for generative AI, with nearly unanimous agreement that it will play a critical role in many areas of life. Thanks to their ease of use, tools like ChatGPT and DALL-E have attracted a ton of attention. There is great potential in using generative AI to improve productivity, streamline design, and operate robots. Holdouts without a fundamental understanding of AI (read: Luddites and tin-foil-hat-clad conspiracy theorists) fear that the hype could lead to unrealistic expectations.

4. MiLlEnNiAlS aRe ThE wOrSt!

If I had a penny for every time someone gave a presentation at an industry event about economics, statistics, or the manufacturing industry’s workforce and nonchalantly called millennials lazy, entitled, and the worst thing to ever come into existence, I’d have enough money for a dozen super PACs to fund my dictatorship of the world (and put all those clowns in a home). Apparently, they can’t get anybody young to work for them. I wonder why!

5. Not this Again...

Yup, 3D-printed meat. For food. Listen, the American food supply and health (namely Big Pharma) industries are already corrupt and broken beyond repair. Seriously, we’ll never see quality health care or food that isn’t poison inside our borders ever again! As an industry – nay, as the greatest industry – can we please not join them? Quick counterpoint: Print me a pizza. Material extrusion and DED totally make sense for every component of a pie… But pretend meat, though, bro? You got me messed up! See you next week.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/