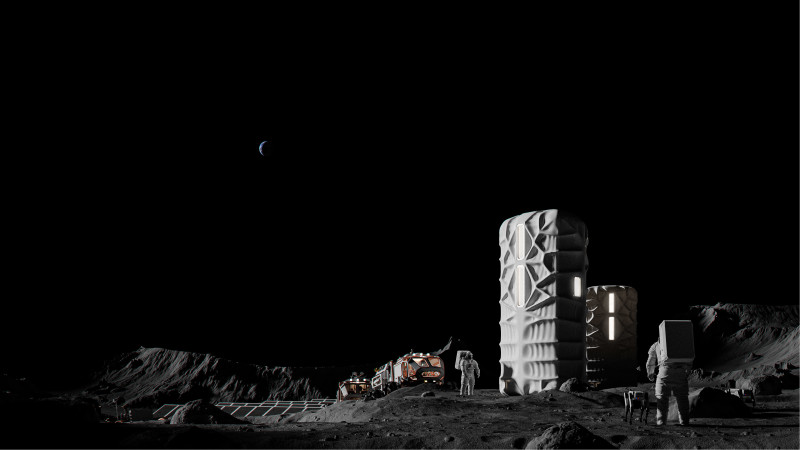

McLean, Va. (September 2, 2022) – How do you build a new house on the moon? With NASA’s upcoming launch of the Artemis 1 Space Launch System rocket, America’s attention is on space. To explore how manufacturing technologies enable sustainable lunar lodging, AMT’s Emerging Technology Center (ETC) at IMTS – The International Manufacturing Technology Show will feature a scaled section of the 23-foot-tall Rosenberg Space Habitat, the world’s tallest 3D-printed polymer structure. The ETC will also feature live demonstrations of the robotic 3D printing technology used to make the space habitat, as well as video interviews with the designers and builders of the habitat.

IMTS 2022 runs Sept. 12-17 at Chicago’s McCormick Place (plan your visit) and is the largest manufacturing technology show in North America. It is considered a must-attend event by OEMs, tier suppliers, contract manufacturers, machine shops, manufacturing engineers, sourcing/purchasing agents, and the 3D printing industry. The ETC, powered by AMT – The Association For Manufacturing Technology (which owns and produces IMTS), is renowned for showcasing projects and disruptive technologies and challenging preconceived notions of how manufacturing performs at its best.

The ETC will also feature the massive machine tools and other manufacturing technologies being used to create the 138-foot-tall Giant Magellan Telescope (GMT). The GMT will be four times more powerful than the James Webb Telescope and 10 times more powerful than the Hubble Telescope. IMTS exhibitors Ingersoll Machine Tools (booth #338004) and Siemens Industry (booths #133346 and #433028) collaborated to produce the space habitat, and Ingersoll is machining the telescope mounting system at its facilities in Rockford, Illinois.

“The public only sees the rocket launches or spectacular images of galaxies that push the boundary of science, but virtually every space or aerospace project involves components manufactured by IMTS attendees using technology from IMTS exhibitors,” says Tim Shinbara, chief technology officer at AMT. “NASA understands that when your supply chain stretches 238,900 miles back to earth and beyond, automated AM systems make the most efficient use of precious cargo space and limited human resources. The lunar habitat and GMT are literal out-of-this-world examples of how digital technologies increase manufacturing efficiency.”

“Even in light of our long history building massive structures for the Department of Defense, I am in awe of the Ingersoll team collaborating with scientists who develop equipment and systems that enable us to explore the universe and work on the moon,” says Jeffrey Ahrstrom, Ph.D., CEO of Ingersoll Machine Tools, part of the Camozzi Machine Tool Group. Ingersoll and sister company Innse-Bernardi have a rich tradition of manufacturing large, complex machines and machinery that require complex tolerances, as well as rigidity, precision, and accuracy while moving.

Tech for Space and Terrestrial Applications.

The GMT will stand 12 stories tall and weigh 2,100 metric tons. The altitude-azimuth mount provides the supporting framework for seven of the world’s largest mirrors, each of which has a diameter of 27.6 feet. The mirrors are so perfect that if they were expanded to the size of the United States, the tallest imperfection would be 2 inches. It can track celestial targets moving across the sky with about 1 arcsec accuracy (1 arcsec = 1/1,296,000 of a turn). Because the huge structure is too heavy to precisely position by mechanical means alone, the telescope mount floats on an oil film 50 microns thick, and it uses Heidenhain (booth #339449) linear encoders for accuracy, the same type of encoders used to position CNC tools.

Ingersoll is fabricating the GMT mount at its new 40,000-square-foot manufacturing, assembly, and testing center in Rockford using one of its largest and most advanced MasterMill systems. MasterMill is the company’s large-format, 5-axis, cross-rail-adjustable gantry system for complex-geometry hard metal components. The gantry has a total work envelope of 25 by 11 by 6.2 meters. Even at that size, the mount is so large that Ingersoll needed to excavate a pit underneath the gantry to avoid violating local building height restrictions. The gantry also needs to be fabricated in two- and three-story segments because of transportation size restrictions on the roads to the Las Campanas Observatory in Chile, where Ingersoll technicians will assemble it with the mount when fabrication is complete in 2025.

The cornerstone of the robotic 3D system in the ETC is the Ingersoll MasterPrint Robotic, a large-volume hybrid system with the ability to seamlessly program, simulate, 3D print, and mill composite parts in a single piece. It uses Camozzi Digital 4.0 technology and the Ingersoll Composite Software Suite for Additive and Automated Composites. The cell pairs Ingersoll technology to Siemens’ latest and most powerful control system, the Sinumerik One, which has digital twin capabilities. The combination of the Sinumerik One and MasterPrint technology is especially suitable for making molds for composites or directly printing parts several meters in volume.

The ETC is located on the Grand Concourse of McCormick Place and the entrance to the North Building. Registration for IMTS for individual visitors is $70 and includes access to all six days of IMTS, nine technology pavilions, and the co-located HANNOVER MESSE USA show, which emphasizes digital technology. IMTS 2022 will occupy more than 1 million square feet of exhibit space and all four buildings of McCormick Place. Booking hotels through Global Housing Solutions, powered by AMT guarantees the lowest room rate and a positive booking experience.

-end-

Image Information

JPG: Lunar Habitat

Caption: To explore how manufacturing technologies enable sustainable lunar lodging, AMT’s Emerging Technology Center (ETC) at IMTS – The International Manufacturing Technology Show will feature a scaled section of the 23-foot-tall Rosenberg Space Habitat.

JPG: GMT_Interior_Front

Caption: To infinity and beyond – the Emerging Technology Center (ETC) at IMTS 2022 explores the technology behind lunar living and astronomy. Visitors can watch live robotic 3D printing of a replica of the Rosenberg Space Habitat and learn about manufacturing components for the Giant Magellan Telescope (GMT), which feature technology from IMTS exhibitors Ingersoll Machine Tools and Siemens Industry.

Links:

LinkedIn: IMTS Chicago

Twitter: #IMTS2022

Facebook: facebook.com/IMTS.show

IMTS YouTube Channel: youtube.com/c/IMTSTV

IMTS – International Manufacturing Technology Show – The largest and longest-running manufacturing technology trade show in the United States is held every other year at McCormick Place in Chicago, Illinois. IMTS 2022 will run Sept. 12-17. AMT – The Association For Manufacturing Technology, which owns and produces IMTS,represents and promotes U.S.-based manufacturing technology and its members – those who design, build, sell, and service the continuously evolving technology that lies at the heart of manufacturing.