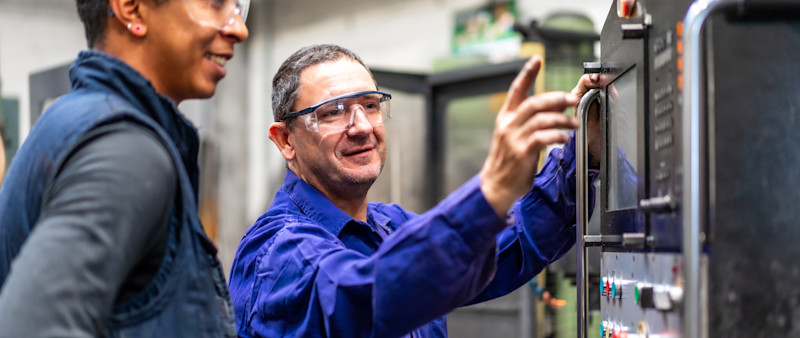

The United States is turning its skilled workforce recruitment and training weakness into a growth offensive. Tech-charged reshoring initiatives are fueling a skilled workforce reboot and redefining common misconceptions of manufacturing jobs.

Explore the vision powering the industry’s resurgence. Reshoring, advanced technologies, and a renewed focus on skills are driving the next era of U.S. manufacturing and shaping its future.

The Reshoring Initiative*, in conjunction with the PMA, AMT, NTMA, FMA, and SME is looking to recognize companies for successful reshoring projects.

More than 500 U.S. manufacturers identify the keys to boosting domestic production: building a skilled workforce, applying total cost of ownership principles, managing costs, and preparing for geopolitical risk.

When a business model works for a century, it’s due to a combination of the strength of its core principles and its ability to adapt to economic, technological, and cultural changes to maintain relevance across multiple generations.

New data reveals OEMs prioritize price, but overlook true sourcing costs. Contract manufacturers say better tools and trained labor are key to restoring U.S. production strength.

Sumitomo Drive Technologies received the 2024 National Metalworking Reshoring Award. The award was given in recognition of their success in bringing manufacturing to the United States through foreign direct investment and to Mexico via nearshoring.

The Reshoring Initiative's 2023 report highlights a robust trend in U.S. manufacturing, with 287,000 jobs announced, driven by essential goods, strategic policies, and responses to global events.

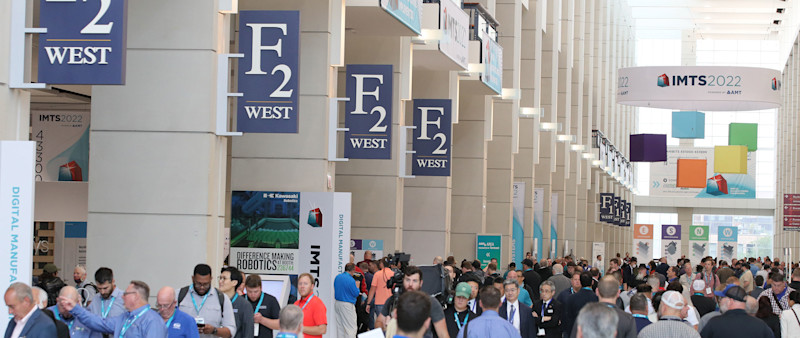

Gain fresh ideas for a more efficient and connected supply chain that boosts profitability. Learn practical strategies from industry leaders at the IMTS 2024 Supply Chain Forum taking place on Wed., Sept. 11.

Is it a good time to make things in the USA? Gather insights on semiconductor manufacturing, reshoring, and tech advancements, uncovering essential strategies for growth and opportunity.