Metal additive manufacturing (AM) has experienced widespread growth in our understanding and curiosity. It has reached an inflection point that will be on full display in the Additive Manufacturing Sector, accelerated by Formnext, at IMTS 2024, held Sept. 9-14 at McCormick Place in Chicago.

In its early phases, metal AM focused on prototyping and low-volume, high-value production. With technology available now, AM implementation has expanded to include mainstream, medium-volume, cost-effective production. As engineers design for AM, they open more applications in the medical, aerospace, and defense industries, which are core markets for IMTS attendees.

“AM technology providers are driving industrialization, process reliability, output, consistency, and ease of use,” says Glynn Fletcher, president of EOS North America (booth #432302), the leading provider of laser powder bed fusion technology. “We are also driving down cost per part through improved process speed and material costs.”

With the shift from specialization to production, AM has become a fully integrated process, and that makes IMTS 2024 a must-attend event for OEMs and job shops that want to expand or explore how to integrate AM into their machining operations.

“IMTS is a complete manufacturing show,” says Jim Hockey, director of business development at Incodema3D, a contract manufacturer producing metal AM components. “We have blended additive and conventional machining methodologies for repeatable, dependable production.”

A tour of Incodema3D’s facility in Freeville, New York, is a microcosm of IMTS. A short list of capabilities includes:

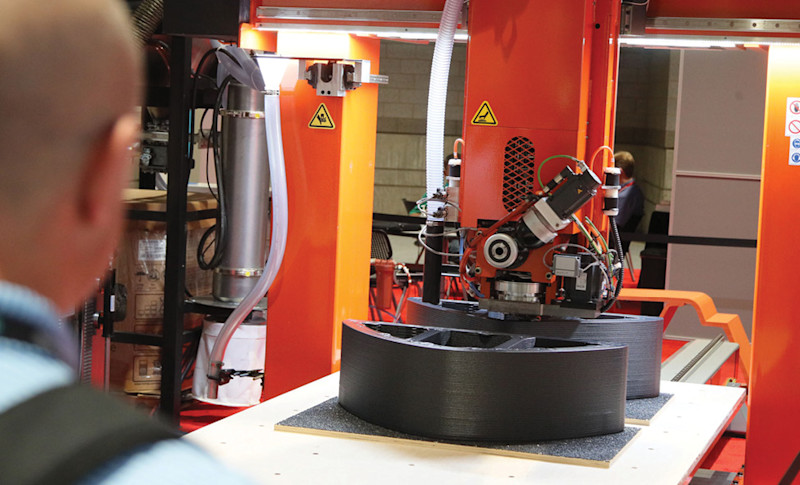

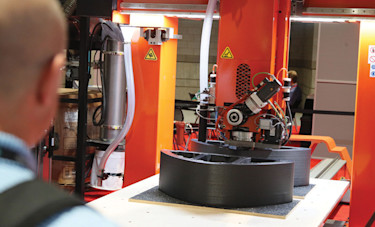

Additive Manufacturing: 23 laser powder bed fusion systems from EOS and metal powders from EOS, 6K Additive (booth #433024), and GE Additive (booth #433200).

Metal Removal: 10 machining centers from Haas (booth #338100), six wire EDMs from Mitsubishi (booth #338129), and a Mazak (booth #338300) i700 Variaxis machining center with a Palletech system for unattended operation. The Mazak system was purchased as a result of vendor evaluation conducted at IMTS 2022.

Quality Assurance: A Zeiss (booth #134302) Contura CMM and Comet 3D blue light vision system.

“We visit more areas of IMTS than ever before,” says Hockey, who has attended the show since the early 2000s. “At IMTS 2024, we plan to explore AI and more robotics to elevate our internal processes.”

Looking Around the Corner

Formnext Chicago, which will be held at McCormick Place on April 8-10, 2025, encompasses the AM technologies at IMTS, and exhibitors will also showcase a broader view of the end-to-end production process of AM, from materials and machinery to software and service bureaus. As an indicator of the show’s scope, consider the Formnext Chicago Founders Club, a veritable who’s who of AM industry leaders who have committed to exhibiting.

“Companies face challenges in cost-effective manufacturing, scaling production, and a gap in innovation expertise,” says Emily Elpes, chief of staff and vice president of marketing for 3DEO, a Founders Club member, IMTS exhibitor (booth #433149), and inventor of the Intelligent Layering® metal AM process. “Formnext Chicago is the place where OEMs and contract manufacturers can go to close their knowledge, production, and cost gaps to move their businesses forward.”

Between the expertise and resources available at IMTS 2024 and Formnext Chicago, the integration of AM into mainstream manufacturing will continue to accelerate.

To read the rest of the Additive Issue of MT Magazine, click here.