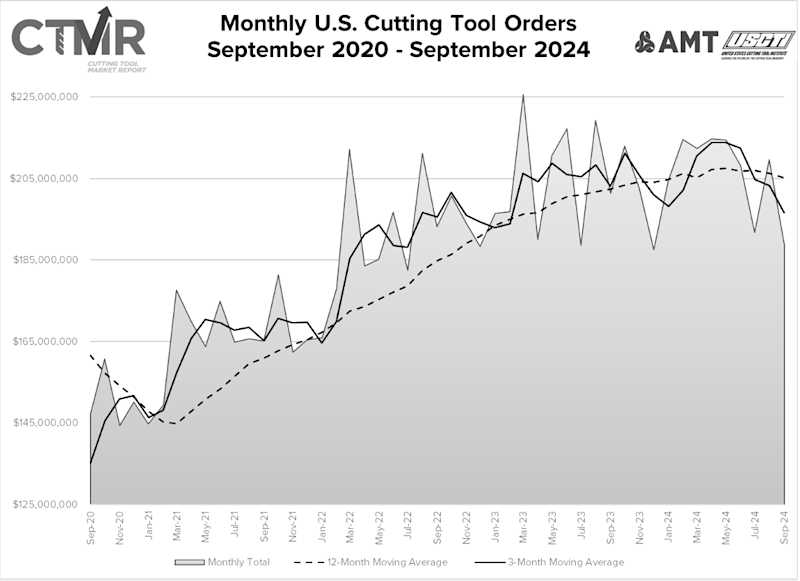

McLean, Va. (November 21, 2024) — Shipments of cutting tools, measured by the Cutting Tool Market Report compiled in a collaboration between AMT – The Association For Manufacturing Technology and the U.S. Cutting Tool Institute (USCTI), totaled $188.7 million in September 2024. Orders decreased 10% from August 2024 and were down 6.3% from September 2023. Year-to-date shipments totaled $1.86 billion, up 0.7% from shipments made in the first nine months of 2023. The year-to-date growth rate has declined every month since April 2024.

“Despite the success and positive energy from IMTS for most exhibitors in Chicago, tooling continues to track at a slower pace,” noted Jack Burley, chairman of AMT’s Cutting Tool Product Group. “Staying consistent with the latest Purchasing Manager’s Index of less than 50, cutting tool consumption is still quite flat, indicating most shops are not running at full capacity. Inflation, interest rates, raw material costs, and pre-election uncertainty put many projects on hold. I do not think we will see any significant improvements until after the first quarter of 2025, when spindle utilization is expected to increase.”

Mark Killion, director of U.S. Industries at Oxford Economics, said: “September shipments were hurt by the machinists union strike at Boeing, eating into one of the largest sources of recent cutting tool demand. In addition, typical seasonal weakness was compounded by retrenchment in output of other customer sectors, such as business equipment, materials, and supplies for construction.”

The Cutting Tool Market Report is jointly compiled by AMT and USCTI, two trade associations representing the development, production, and distribution of cutting tool technology and products. It provides a monthly statement on U.S. manufacturers’ consumption of the primary consumable in the manufacturing process, the cutting tool. Analysis of cutting tool consumption is a leading indicator of both upturns and downturns in U.S. manufacturing activity, as it is a true measure of actual production levels.

The Cutting Tool Market Report is jointly compiled by AMT and USCTI, two trade associations representing the development, production, and distribution of cutting tool technology and products. It provides a monthly statement on U.S. manufacturers’ consumption of the primary consumable in the manufacturing process, the cutting tool. Analysis of cutting tool consumption is a leading indicator of both upturns and downturns in U.S. manufacturing activity, as it is a true measure of actual production levels.

# # #

AMT – The Association For Manufacturing Technology represents and promotes U.S.-based manufacturing technology and its members – those who design, build, sell, and service the continuously evolving technology that lies at the heart of manufacturing. Founded in 1902 and based in Virginia, the association specializes in providing targeted business assistance, extensive global support, and business intelligence systems and analysis. AMT is the voice that communicates the importance of policies and programs that encourage research and innovation, and the development of educational initiatives to create tomorrow’s Smartforce. AMT owns and manages IMTS – The International Manufacturing Technology Show, which is the premier manufacturing technology event in North America.

The United States Cutting Tool Institute (USCTI) was formed in 1988 and resulted from a merger of the two national associations representing the cutting tool manufacturing industry. USCTI works to represent, promote, and expand the U.S. cutting tool industry and to promote the benefits of buying American-made cutting tools manufactured by its members. The Institute recently expanded its bylaws to include any North American manufacturer and/or remanufacturer of cutting tools, as well as post-fabrication tool surface treatment providers. Members, which number over 80, belong to seven product divisions: Carbide Tooling, Drill & Reamer, Milling Cutter, PCD & PCBN, Tap & Die, Tool Holder and All Other Tooling. A wide range of activities includes a comprehensive statistics program, human resources surveys and forums, development of product specifications and standards, and semi-annual meetings to share ideas and receive information on key industry trends.

# # #