A new one-year program led by Somerset Community College (Somerset, Kentucky) is helping impoverished and exploited people in Kentucky get a new lease on life by introducing them to 3D-printing technology.

Funded by a grant from the USDA Rural Development program, Somerset’s new initiative – Elevate Kentucky through Additive Manufacturing (EKAM) – is providing 3D-printing equipment, training, and support to two small businesses, Red Bird Mission and Refuge for Women. The businesses employ and support impoverished individuals and victims of human trafficking, respectively.

EKAM is bringing the power of additive manufacturing to these businesses to enhance their Survivor Made products, craft marketing programs, and increase artisan product lines. Participants will use 3D technology to design and produce sellable craft products, such as jewelry, as well as tools and jigs to enhance their existing manufacturing capabilities.

Transformative Experience

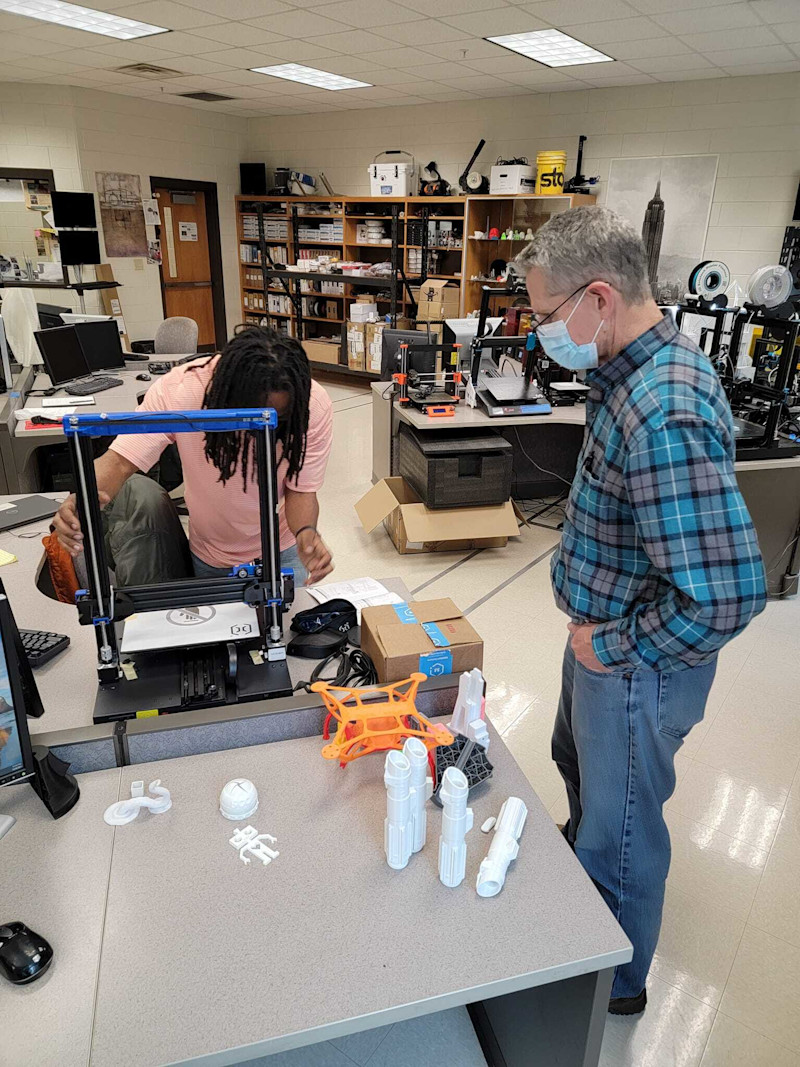

The Additive Manufacturing Center (AMC) located at Somerset Community College has been helping businesses across the state in 3D printing for over seven years, so expanding into the EKAM program was a natural next step for Eric Wooldridge, professor and director of the AMC.

“We had the mindset that additive technology could be used to improve the quality of someone's life,” Wooldridge says. “We wanted to bring advanced manufacturing to the grassroots folks who are often the most creative, and give them the power to make products that are manufacturer-level quality for themselves, and inspire that ability to change one's life through innovation and creativity.”

Career Skills

This program is not only helping two small businesses grow, it’s teaching people new skills that may lead to careers in manufacturing.

“The whole goal of the program is to take those impacted from human trafficking and impoverished regions, re-educate and reorient, and then put them back into the workplace. What greater skill could we give them in defining their own destiny than advanced manufacturing technology?” Wooldridge says.

Training and Equipment

Replicating a remote training program developed for teaching during COVID, Wooldridge is providing participants with eight-to-ten weeks of remote classes, video tutorials, and training materials. The first lessons are in parametric modeling using Fusion 360 software from Autodesk Inc.(IMTS booth: 133310).

“Autodesk has been very gracious to support this project by giving the software to the participants for free,” Wooldridge states. “That’s a big deal because it allows us to teach them the additive manufacturing mentality through design, first and foremost. Then we will shift them to the equipment, train them on how to use the hardware, and then work with them to develop products.”

Wooldridge’s experience enables him to choose, negotiate pricing for, and purchase equipment that’s been tested in the AMC lab for hundreds of hours. In addition to low cost, he looked for options with the potential for future improvements so the equipment will be continually supported and upgradeable. In partnership with Matterhackers, each location will receive a full lab of equipment that includes five Artillery Sidewinder X-1 3D printers, one Elegoo Mars 2 Pro 3D Printer, all necessary accessories, and a variety of filaments (metal, carbon fiber, polycarbonate, PETG, TPU, and wood).

Wooldridge points out that without partners like Matterhackers, Autodesk, and the USDA, projects like this simply could not be possible. “On the surface, projects like this seem fairly straightforward, but the reality is that it takes a lot of work and a team of dedicated partners; folks that truly want to make a difference in the lives of others, and truly believe in the potential of people.”

The Future of 3D printing

After EKAM ends in September 2022, Wooldridge plans to scale up and partner with larger NGOs that want to fund similar initiatives. His goal is to introduce 3D printing broadly around the country and the world.

“From the hobbyist farmer to the surgical professional, we want to make additive manufacturing accessible to everyone,” Wooldridge says. “It will change the way that we look at manufacturing, design, sustainability, and true product value.”