The biggest obstacle to skills training and successful apprentice programs is recruitment, specifically overcoming the “college for all” belief that the route to career and financial success starts with a university degree. The unique asset of this series is a collection of brief bios of industry leaders who started as apprentices and achieved career success beyond that of most university graduates. I believe that, on average, they earn substantially more than the median income of those who hold Ph.D.s and professional degrees.

Key to Reshoring A strong, skilled workforce is key to reshoring and manufacturing growth. The United States will likely need 3.8 million new manufacturing employees by 2033, but a 1.9 million employee deficit is expected by Deloitte and the Manufacturing Institute if the skills-gap is not dealt with effectively.

A deficient skilled manufacturing workforce slows or caps the reshoring trend. My objective is for reshoring to increase U.S. manufacturing by 40%. To do that, we need 30% more employees, assuming productivity increases. That increases the 1.9 million employee deficit to about six million workers.

Expanding our manufacturing apprenticeship program to the level found in Germany and Switzerland is key to reducing the workforce deficit. A properly skilled workforce will increase the rate of reshoring sufficiently to balance our trade in goods, increase global competitiveness, and develop tomorrow’s industry leadership, today.

Apprenticeship — The New Gold Standard Apprenticeship is “an industry-driven, high-quality career pathway where employers can develop and prepare their future workforce, and individuals can obtain paid work experience, classroom instruction, and a portable, nationally-recognized credential.”

Apprenticeships are the new gold standard. The United States will sustain manufacturing jobs at home and reshore millions of manufacturing jobs when its apprenticeship system is transformed to world class.

We advocate for apprenticeship loans that would make it more affordable for companies to have apprentices. Today, if companies pay enough to get a good apprentice, the company often loses money if the apprentice graduate quits for higher pay. The national ROI on apprentice loans would be much higher than on most college loans.

Strong Leadership and Apprenticeship Strong industry leadership is of central importance to help set standards, understand industry trends and have a voice in industry regulations and policies. Some of our most successful manufacturing industry leaders built their careers through apprenticeship. Let’s explore how the career of Harold Schoch, who recently retired as CEO of Fives Machining Systems, Inc., began through an apprenticeship.

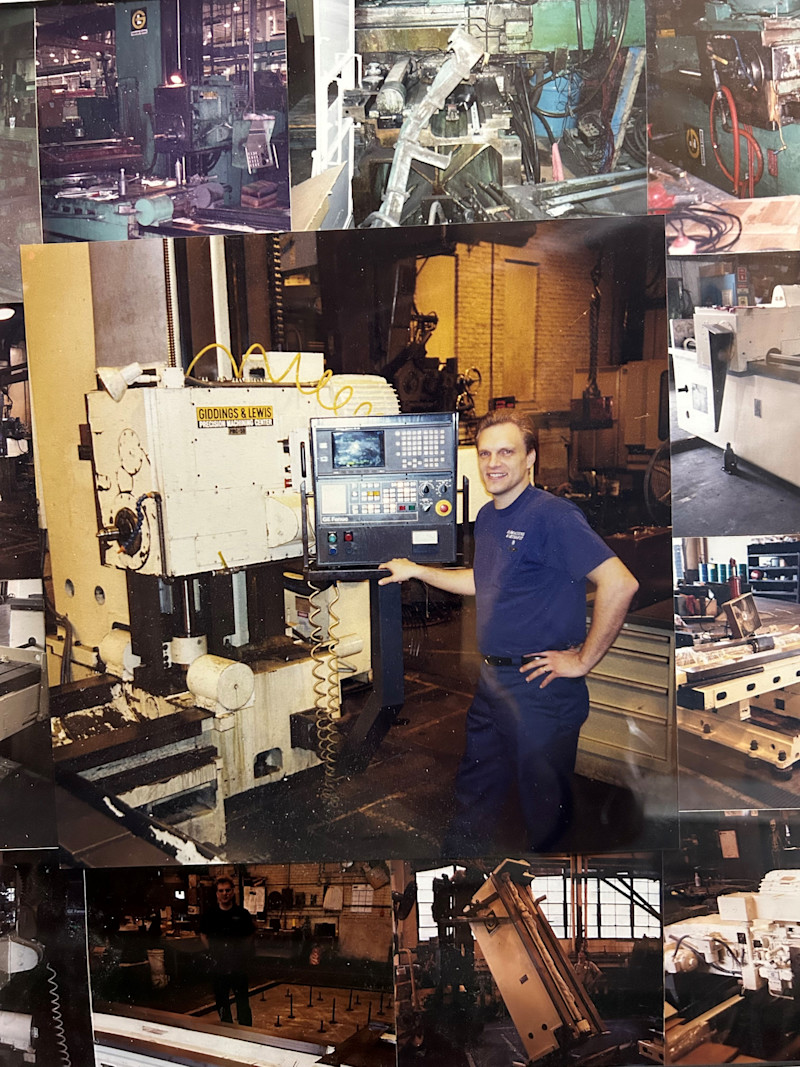

Schoch comes from a long line of machine tool builders that spans five generations. Schoch proudly proclaims, “I began my career in 1979 with an apprenticeship at the American Tool Works company, where I was blessed to have studied under Master Mechanics Ed Hoffmeier and Earl Singleton, two of the most talented machine tool specialists in the industry.”

After completing his apprenticeship, Schoch left American Tool Works to accept a position at his great grandfather George Schoch’s alma mater, LeBlond Machine Tool Company in Hyde Park, Ohio. There he was mentored by specialists in machine tool geometry (scraping), unit assembly, hydraulics, and general assembly.

Schoch continued to sharpen his craft and become well rounded in multiple facets of the machine tool industry. Schoch’s talents were crafted on the production floor, in field service, and in various management roles, eventually leading to a 16-year position as vice president of Re-Machine & Retrofit Company where he was mentored by Gary Smith and Bob Wethington.

Benefits of Deep Industry Knowledge Schoch’s deep industry knowledge prepared him for senior leadership and ultimately inspired him in 2003 to launch his family business, Machine Tool Solutions Unlimited, LLC. The business quickly became a leader in the industry providing a wide range of services to customers, including machine tool rebuilding, control retrofits, preventive maintenance, calibration, and repair services.

The success of the business positioned it as an appealing acquisition, and in October 2009 Schoch sold Machine Tool Solutions Unlimited to Konecranes, adopting the name Konecranes, Machine Tool Service in 2010. The acquisition would facilitate Konecranes’ maiden launch of their machine tool presence in North America and position them as a leader in the industry.

In 2017 Konecranes acquired global competitor Demag, leading to the decision to sell their machine tool service business so they could focus exclusively on their core business. Schoch was asked to select a buyer and handle the negotiations to “safe harbor the employees to a new home.” Schoch selected Fives Machining Systems, Inc. and the deal was finalized in January 2019. This acquisition would make Fives Machine Tool Services & Solutions the largest machine tool rebuilder and retrofitter of Siemens and Fanuc CNC control systems in North America.

Training - Always a Priority Schoch is a huge supporter and public promoter of the Reshoring Initiative’s goal of reshoring five million manufacturing jobs to the United States and shares the belief that although reshoring is a huge first step, it must be followed closely by the training and development of employees. If we are serious about sustaining the renaissance that is occurring in U.S. manufacturing, it must be reflected in how businesses invest in the training programs for their employees.

“The training and development of the teams that I have led over the years was always a priority and paramount to our success,” says Schoch. “My mentors charged me with ‘paying it forward’ for the next generation of skilled trades, so I didn’t want to let them down. It is because of the exceptional training I was blessed to receive, and the experiences I gained from rebuilding and retrofitting machine tools, that I championed the launch of our Fives High Precision Machines (HPM) Training Academy. I am grateful that our chairman, Frederic Sanchez, joins me in my dedication to the development of our employees and supported the launch of the Academy so our team is equipped to provide the best customer experience possible.”

Schoch is honored to be one of five business leaders to sit on Fanuc’s inaugural “Authorized System Integrators Leadership Council” and has used his relationships with Siemens to help Fives Machining Systems, Inc. (Cincinnati, Giddings & Lewis, and Machine Tool Services & Solutions) become a participant in the “Siemens Solutions Partner” program. Schoch’s apprenticeship training, hard work, determination, and deep industry knowledge have led to a notable career.

Nominate Leaders That Began As Apprentices In this apprenticeship and leadership series, we will look at the unconventional pathways of other successful manufacturing leaders. We will highlight trailblazers like Glynn Fletcher, president of EOS North America; Andy Palmer, director at Nissan and CEO for Aston Martin; Gisbert Ledvon, vice president of marketing at Heidenhain North America; Crispin Taylor, president and CEO of INDEX Corp.; and Markus Stolmer, president and CEO at United Grinding North America. Stay tuned for part two.

Do you know an industry leader who started as an apprentice? We are looking for individuals at equipment suppliers, OEMs, and job shops. We will use their stories to promote manufacturing apprenticeships nationwide and recognize some of our industry’s leaders. Proudly send me your own case or point me to a friend. Trade associations: please suggest relevant leading members. Equipment suppliers: suggest colleagues and customers.

Are you thinking about reshoring?

Let’s collaborate to support skilled workforce development and rebuild the U.S. manufacturing base. For help, contact me at 847-867-1144 or email me at harry.moser@reshorenow.org. Our main mission is to get companies to do the math correctly using our free online Total Cost of Ownership Estimator® (TCO). By using TCO, companies can better evaluate sourcing, identify alternatives, and even make a case when selling against offshore competitors.