“I have not failed, but found 1000 ways to not make a light bulb.”

– Thomas Edison

1. Challenges Faced by Manufacturers

Recruitment and retention are still problems for most manufacturers. Technology adoption is another big problem for small to medium-sized companies. These companies are seeking cost-reduction strategies and identifying growth opportunities.

2. No More Greasing Ball Bearings???

Oh, that’s right. The plastic ball bearing is a thing in the industrial space. The material development of polymers continues to make inroads in traditionally metal-only applications.

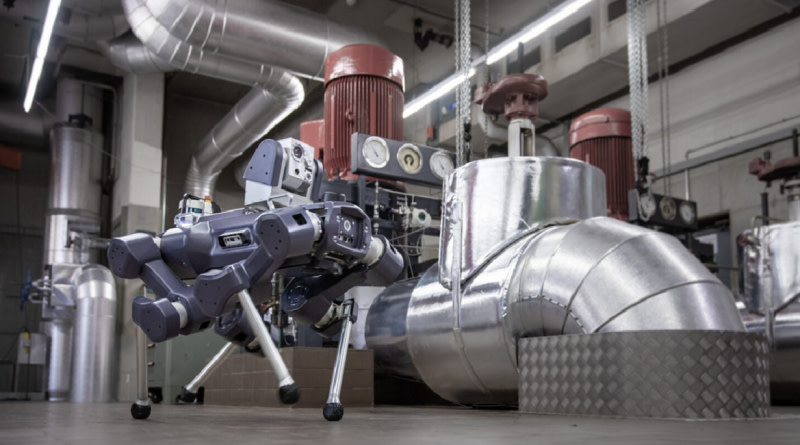

3. In-Field Inspection

As plants and facilities grow, the need for automated inspection becomes more important. Now, this can be automated – like completely automated. Using quadruped AGVs, the assessment of facilities can be handled autonomously.

4. Making Additive More Better

Seems like we found another material gap in additive: functional materials in power applications. This research team is looking into additive materials for semiconductors, batteries, and electric motors. This could be an interesting reset on the design of electric motors for industrial applications.

5. Automating Customers

There have been a lot of discussions around automating the last mile of delivery service. A different approach is to automate the entire store. Similar to a vertical carousel storage system, this new tech offers a new approach to providing goods to the end customer.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/