Is metrology the end of the manufacturing process, or is it just the beginning? Exhibitors in the Quality Assurance Pavilion at IMTS 2022 are unveiling a host of new products to optimize workflow, improve manufacturability, and increase quality.

Technologies making their pavilion debut include: MTConnect-enabled instruments that offer:

Remote monitoring of machine status via the cloud with a smart phone app.

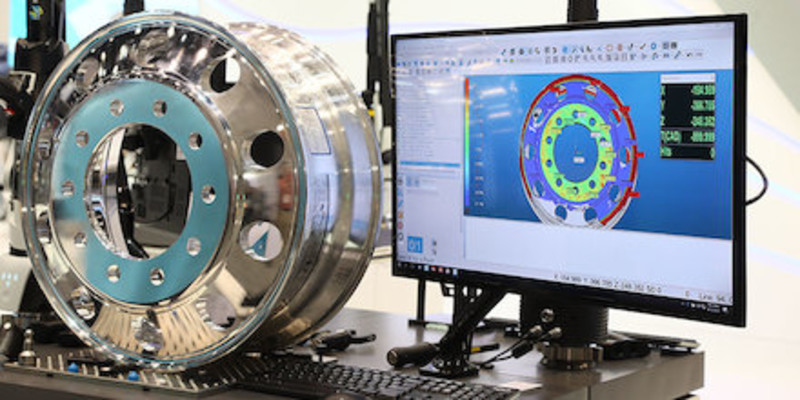

Automatic creation of measurement programs from 3D CAD models.

Measurement of fragile parts using non-contact optical techniques.

Self-learning (AI) CMM measurement programs that learn not to measure characteristics that do not impact quality.

CT and CMM systems that can create a digital twin by measuring a real product.

As manufacturers in the automotive, aerospace, medical, electronic, and other industries face more stringent quality and compliance demands, they need more powerful quality assurance solutions. For example, CT and X-ray technology are now being used to verify the quality of electric vehicle (EV) battery assemblies, 3D printed components, and other items that need inspection of internal structures.

EVs will be a hot topic at IMTS 2022. Without the noise of a combustion engine to mask the sound of poorly meshing gears or loose parts, tolerances need to be tighter. Job shops and OEMs will find new solutions specific to EVs throughout the show, but especially in the Quality Assurance (QA), Metal Removal and Gear Generation Pavilions at IMTS 2022.

Another trend to look for in the Quality Assurance Pavilion is an “integrated measuring experience,” which means that images and data can be shared on a network of instruments that share common software, eliminating time-consuming manual file uploads. Reporting software can create, analyze, and plot measurement results from thousands of data points (e.g., “big data”) and then share the results to other machines, plants, or locations to gain insights.

Finally, the explosive growth in automation also extends to metrology. Just as CNC manufacturers will debut “robot ready” machining centers, exhibitors in the QA Pavilion are making sure that their measurement machines can communicate with robots to enable automated part load/unload to improve productivity.

Register now for IMTS 2022, Sept. 12-17, McCormick Place, Chicago, Ill.