To build things better, sometimes you need to tear them down, and there’s no one better than Sandy Munro, known as the “Teardown Titan.” Munro and his team of lean manufacturing experts at Munro & Associates have deconstructed every almost EV on the market. They share their findings on the “Munro Live” YouTube channel, which has 515 videos and 383,000 subscribers. OEMs contract with Munro for its services to learn how to increase product value, quality, and profit through better engineering and assembly.

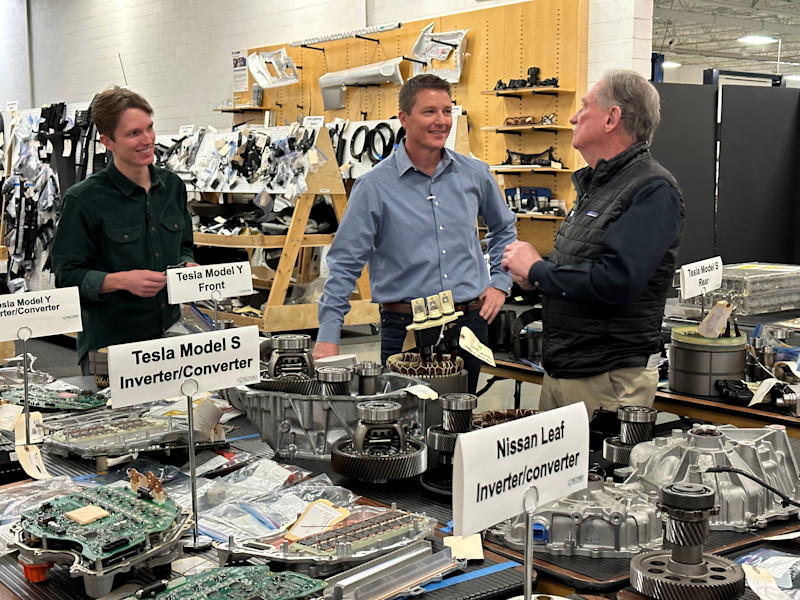

In Season Three, Episode One of the IMTS+ Original Series “Manufacturing Explorers,” brought to you by Mazak, Munro walks my son Max and me through rows upon rows of disassembled EV car bodies, motors, transmissions, and batteries. We learn the good, the bad, and the lean of EV design, starting with Tesla Model 3. Munro & Associates took the car to pieces in 2017.

“When we tore it apart, I was very, very unhappy. The fastening was ridiculous,” says Munro. The Model 3 used more than 120 parts and fasteners, four different fastening methods, and three different materials. It resembled a science experiment.

By 2020 and the Model Y, the parts count was down to two large castings plus a plastic liner cover, two straps with 40 fasteners, and used all aluminum. Eight months later, another iteration came out. “This Model Y has a single aluminum casting. Consequently, even though aluminum is more expensive than steel, when you look at total accounted cost, this Model Y was cheaper than the Model 3 and its 120 parts.”

After looking at EV bodies, we focused on electric motors and transmissions. “I was really curious about the manufacturing process,” says Max. “The size and power difference between an electric motor and an internal combustion engine is surprising.”

“The cost and weight of an EV motor is practically dirt compared to even the most efficient internal combustion engine,” says Munro. He also notes that EVs require just a fraction (perhaps 1/20th) of the manufacturing space.

To conclude the Episode, we examined a deconstructed Model Y battery. Rather than one giant battery, it is made up of 4,680 palm-sized “cans” embedded in fire-resistant pink foam.

“I loved learning why Munro deconstructed these cars so clients can learn how to improve and lower cost,” says Max.

See how the Teardown Titan tears down to build back better in Seasons Three, Episode One of “Manufacturing Explorers,” an IMTS+ Original Series, on IMTS.com. But don’t stop there — continue your own exploration of innovation by catching Seasons One and Two as well as dozens of other shows and articles. IMTS+ is a treasure trove celebrating our vibrant manufacturing technology community.