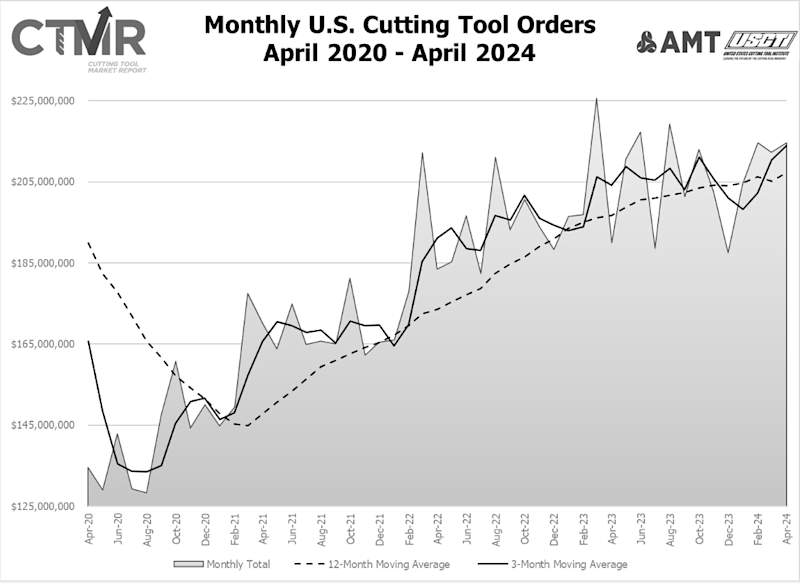

McLean, Va. (June 12, 2024) — Shipments of cutting tools, measured by the Cutting Tool Market Report compiled in a collaboration between AMT – The Association For Manufacturing Technology and the U.S. Cutting Tool Institute (USCTI), reached $214.7 million in April 2024. Orders increased 1.1% over March 2024 and grew by 13% over April 2023. Year-to-date shipments totaled $846.1 million, nearly 5% above shipments made in the first four months of 2023.

“While April 2024 shipping numbers do show an increase from those of 2023, caution continues due to many uncertainties ahead for the remainder of 2024,” said Steve Boyer, president of USCTI. “Uneven growth and turbulence have continued to impact cutting tool orders through the first quarter of 2024, and there have been some downgrades in expected needs from the aerospace sector, leading to stagnation in new orders.”

Costikyan Jarvis, president of Jarvis Cutting Tools, expanded on Boyer’s analysis, saying, “The industrial sector of the economy continues to move sideways. While the value of cutting tool shipments is up about 5% over last year, the flatter growth rate in units shows that inflationary pressures are still present.”

Looking forward, Jarvis said: “There are two big ‘ifs’ that could result in improved demand during the second half of the year. The first is that the overall production remains consistent. The second is if Boeing can start ramping up production of the 737 to the FAA limit of 38 per month. If those two things can happen, the cutting tool industry might be positioned for growth in both revenue and volumes.”

The Cutting Tool Market Report is jointly compiled by AMT and USCTI, two trade associations representing the development, production, and distribution of cutting tool technology and products. It provides a monthly statement on U.S. manufacturers’ consumption of the primary consumable in the manufacturing process – the cutting tool. Analysis of cutting tool consumption is a leading indicator of both upturns and downturns in U.S. manufacturing activity, as it is a true measure of actual production levels.

Historical data for the Cutting Tool Market Report is available dating back to January 2012. This collaboration of AMT and USCTI is the first step in the two associations working together to promote and support U.S.-based manufacturers of cutting tool technology.

The graph below includes the 12-month moving average for the durable goods shipments and cutting tool orders. These values are calculated by taking the average of the most recent 12 months and plotting them over time.

AMT – The Association For Manufacturing Technology represents and promotes U.S.-based manufacturing technology and its members – those who design, build, sell, and service the continuously evolving technology that lies at the heart of manufacturing. Founded in 1902 and based in Virginia, the association specializes in providing targeted business assistance, extensive global support, and business intelligence systems and analysis. AMT is the voice that communicates the importance of policies and programs that encourage research and innovation, and the development of educational initiatives to create tomorrow’s Smartforce. AMT owns and manages IMTS – The International Manufacturing Technology Show, which is the premier manufacturing technology event in North America.

The United States Cutting Tool Institute (USCTI) was formed in 1988 and resulted from a merger of the two national associations representing the cutting tool manufacturing industry. USCTI works to represent, promote, and expand the U.S. cutting tool industry and to promote the benefits of buying American-made cutting tools manufactured by its members. The Institute recently expanded its by-laws to include any North American manufacturer and/or remanufacturer of cutting tools, as well as post-fabrication tool surface treatment providers. Members, which number over 80, belong to seven product divisions: Carbide Tooling, Drill & Reamer, Milling Cutter, PCD & PCBN, Tap & Die, Tool Holder and All Other Tooling. A wide range of activities includes a comprehensive statistics program, human resources surveys and forums, development of product specifications and standards, and semi-annual meetings to share ideas and receive information on key industry trends.

# # #