Robotic welding, 3D printing, and smart wireless communication systems are just a few of the latest classes students can take in new advanced manufacturing education centers popping up across the country.

Rewarding Careers

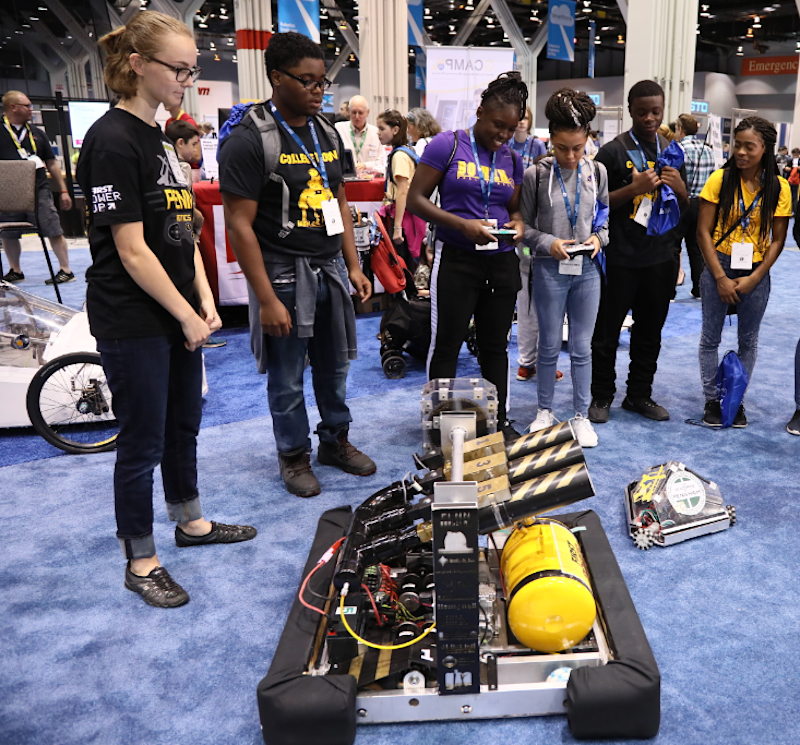

“It is very encouraging to see new investment in technical curricula for advanced manufacturing as it leads to careers that are incredibly rewarding – both on a personal level and, of course, financially,” says Greg Jones, Vice President of Smartforce Development at AMT (The Association For Manufacturing Technology), which owns and operates IMTS (The International Manufacturing Technology Show). Jones leads the Smartforce Student Summit event at IMTS, which was re-imagined as the Smartforce Career & Education Experience during the pandemic and included engaging online content to serve as a launch point for students to explore the manufacturing technology classroom of the future.

Innovation and Growth

Not only will these investments ensure a talented workforce is available to support local manufacturing technology businesses, they will also spur and attract new businesses. “When you make things, often you iterate, creating a culture of innovation,” says Jones “Many in advanced manufacturing go on to become entrepreneurs, advance their careers toward leadership or research and development, and even apply their skills to other industries.”

Broad Spectrum of Industries

Advanced manufacturing touches a wide realm of growing industries that includes electric and autonomous vehicles, deep-space exploration, next-generation medical implants and devices, new energy-saving construction techniques, and more.

New advanced manufacturing technology centers are underway at:

College of Lake County, Advanced Technology Center, Gurnee, Ill. CLC recently bought an old Lowes home improvement facility and is turning it into a premier advanced technology center. Lake County is the one of the largest manufacturing counties in Illinois.

Cleveland Community College, Advanced Manufacturing Center, Rocky Mount, N.C. In April 2021, state legislators, local officials, and college trustees and staff gathered for the official groundbreaking of their new 30,000-square-foot advanced manufacturing center, which was funded by state and private foundations. CCC worked with the local Economic and Workforce Development corporation, including a local advisory board representing 40 different industries.

Ozarks Technical Community College, Center for Advanced Manufacturing, Springfield, Mo. The $40-million, 120,000-square-foot center is underway and is the largest capital project in the history of the college. The center was made possible after citizens voted to approve an increase in property taxes, with additional money from state funding and private donations.

Bishop State Community College, Advanced Manufacturing Center, Mobile, Ala. Currently under construction, BSCC is touting this $17-million, 80,000-square-foot facility as the premier workforce development center for the Gulf Coast region. (BSCC is currently accepting applications for naming rights to its new AMC.)

Industrial Technologies Offer Something for Everyone

“These are significant initiatives. They are employing a strategy for staying ahead of the skills gap in advanced manufacturing in this critical period coming out of the pandemic,” says Jones. “There is a need to educate, upskill, and reskill individuals, especially in areas of new, transformative technologies like additive manufacturing, artificial intelligence with a focus on machine learning, augmented reality, automation and robotics, digital twins, and generative design.”

The facilities will also offer courses on and certificates in mechatronics, computer aided design (CAD), computer numerical controlled (CNC) machining, CNC automation cells, hydraulics and pneumatics, welding simulators, computer networking, and precision machining.

Wanted: Skills!

“Even though manufacturing was recognized as an essential industry during the pandemic, schools were in various states of being open. As a result, the skills gap widened in advanced manufacturing,” says Jones.

As of May 2021, the Bureau of Labor Statistics (BLS) reported more than 9.3 million open jobs in the United States, and 814,000 of those jobs were in manufacturing – an all-time record. “These new school projects are a good first step toward filling the employment gap,” says Jones. “I anticipate that we will see further investment in new ATCs around the country because addressing the skilled workforce crisis is a top priority for government, businesses, schools, and workers.”

Explore Galore!

To gain ideas about the emerging technologies and exciting careers in advanced manufacturing, visit IMTS.com/Smartforce.

Watch now! The Show - Smartforce Student Summit

What is an Advanced Technology Center?

An Advanced Technology Center, sometimes called an Advanced Manufacturing Center or a Manufacturing Technology Education Center, is a community-based or regional education and workforce development facility that provides career and technical education by way of hands-on learning, often coupled with virtual- and augmented-reality experiences, about the machinery, technology, devices, and digital equipment that U.S. companies use in their manufacturing processes to be more productive, innovative, and globally competitive.

The curriculum ranges from computer numerical controlled (CNC) machining (subtractive manufacturing), 3D printing (additive manufacturing), computer aided design and computer aided manufacturing (CAD/CAM), automation and robotic integration, mechatronics, and ultra-precise dimensional measurement.

Artificial intelligence, machine learning, and data analytics, spurred on by connected devices or the Industrial Internet of Things (IIoT), are also technologies taught. Students can be classified as post-secondary students, apprentices, or incumbent workers who are attending classes for specific re-skilling or upskilling.

Students can earn degrees, certificates, industry-recognized credentials, and micro-credentials in specific curriculum and technology areas. Graduates go on to career pathways in aerospace, defense, biomedical technology, job shops and broader manufacturing, mechanical and industrial technology, and engineering fields.