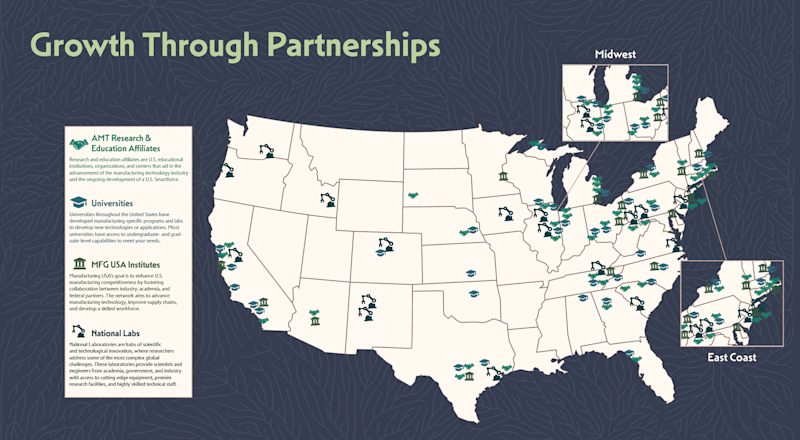

The United States is full of opportunities to develop new technologies, applications, and a next-gen Smartforce. However, growth for a single company is difficult because of risks, time, and technological capability. Why not partner with an entity that can supplement what you don’t have? Technology development partners can take multiple forms. These include universities, Manufacturing USA institutes, the Department of Energy’s national laboratories, and AMT’s research and education affiliates.

Universities

Educational institutions offer an array of skills and technology. Universities throughout the United States have developed manufacturing-specific programs and labs to develop new technologies or applications. Most can provide your company with access to undergraduate- and graduate-level capabilities depending on your needs. For example, AMT has partnered with Virginia Tech to assess the capabilities required to implement foundational digital manufacturing technologies, and these projects have been completed with junior and senior students.

Here are some key elements to consider when partnering with a university:

University specialization

Timeframe for projects

Facility expertise

Your time for mentoring and coaching

On-site technologies

Intellectual property retention or sharing

Cost structure

Here are some example institutions:

MFG USA Institutes

Manufacturing USA (MFG USA) was established in 2014 as the National Network for Manufacturing Innovation. Its goal is to enhance U.S. manufacturing competitiveness by fostering collaboration between industry, academia, and federal partners. The network aims to advance manufacturing technology, improve supply chains, and develop a skilled workforce. The initiative began in 2011 with the formation of the Advanced Manufacturing Partnership based on a recommendation from the President's Council of Advisors on Science and Technology. This partnership identified collaboration opportunities to boost advanced manufacturing in the United States. In 2014, the Revitalize American Manufacturing and Innovation Act (RAMI Act) was passed, officially authorizing the program.

When considering joining an MFG USA institute, keep the following in mind:

Each facility has a different membership model

Intellectual property retention or sharing

Cost-sharing model for project

Industry partner for projects

Project call cycles

Who is providing the technologies, material, and time?

The list of MFG USA institutions can be found here.

National Labs

The Department of Energy’s national laboratories are hubs of scientific and technological innovation, where researchers address some of the world's most complex challenges. These labs provide scientists and engineers from academia, government, and industry access to cutting-edge equipment, premier research facilities, and highly skilled technical staff.

When partnering with a national lab, here are a few key points to keep in mind:

Is the problem novel?

What is the go-to-market strategy after development?

Does this project require national equipment?

What are the intellectual property considerations?

What priority is this project with the current workload?

A list of national labs is located here.

AMT’s Research and Education Affiliates

AMT’s research and education affiliates are U.S. educational institutions, organizations, and centers that aid in the advancement of the manufacturing technology industry and the development of a U.S. Smartforce. Here are some key points when searching for R&E affiliates:

Which segment in the organization needs support?

What are networking opportunities?

What learning and development opportunities are offered?

What markets do they support?

AMT R&E companies can be found here. One or more of these facilities is right for your business. Choosing which university, MFG USA institute, or national lab to partner with requires understanding your strategy, technology knowledge, and go-to-market strategy. AMT’s Research Services and technology teams can help you navigate your options. Submit a research request to learn more.

To read the rest of the Workforce Issue of MT Magazine, click here.