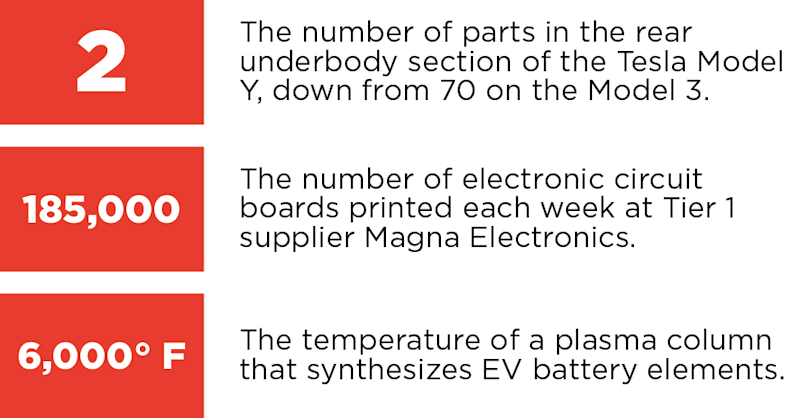

Numbers matter in Season Three of “Manufacturing Explorers,” an IMTS+ Original Series, which premieres on Sept. 28 on IMTS.com. Here are three critical numbers encountered by show stars (and father-son duo) Max and Travis Egan as they explored the automotive industry:

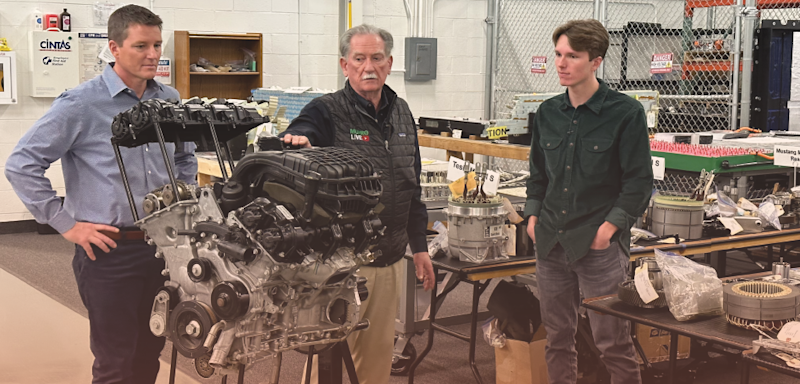

Season Three starts with a visit to Munro & Associates in Auburn Hills, Michigan. Sandy Munro, known as the “Teardown Titan,” deconstructs and analyzes vehicles, and he has particularly focused on EVs. The tour starts with Munro explaining the genius behind the Model Y design and really any design that consolidates parts for optimization. Munro calls items such as bolts “unfasteners.” Any design that eliminates a connection is one less thing to go wrong, and it’s something he happily points out as part of Munro’s redesign services. Munro also answers Max’s questions about EV battery recycling and battery life (you’ll be surprised), explores the design of electric motors (they are only about the size of a basketball!), and provides insights into design and manufacturing efficiency. In a twist of fate, a fender bender at home provides the opportunity to rent a Model Y, and it’s a contest between Max and Travis to see who becomes the bigger fan and why.

In the second episode, Max and Travis travel to Magna to meet up with another father-son duo, general manager John Cunningham and manufacturing engineer Alex Cunningham. If you drive a modern vehicle, chances are you’ve experienced one of the millions of sensors manufactured by Magna, including those used for cruise control, parking assist, object detection, and tailgate cameras. Watch as Max experiences one of Magna’s newer innovations, the Toyota Tundra trailer backup assist, then gets a firsthand look at how printed circuit boards are made.

In the final episode of the third season, Max and Travis explore what might be the key to EV growth: the synthesis of lithium-ion anode and cathode battery materials. Based in North Andover, Massachusetts, 6K Inc. created the UniMelt® system, a production-scale microwave plasma process that produces critical materials. Pour in feedstock at the top, zap it with an ultra-high temperate 6,000-degree plasma, and high-value materials come out at the bottom. While conventional battery material production processes made from lithium, nickel, and cobalt pose geopolitical risks, cause mining damage to the environment, and are fraught with fair labor issues, UniMelt® is a green process that enables a diverse and reliable supply chain for EV battery components leveraging both domestic and recycled feedstock.

Season Three also bids a bittersweet farewell to its current hosts, as it’s the final season with Travis and Max. The show started with Max as a young mechanical engineering undergraduate and Travis introducing him to his world of manufacturing. After one pandemic, five years, two degrees, and 10 road trips with dad and a camera crew, Max is now pursuing his dream career as a lead analyst in the renewable energy industry.

Buckle up and join Max and Travis Egan as they talk about the thrills of visiting innovative automotive companies in the premiere of the third season of “Manufacturing Explorers,” an IMTS+ Original Series, at IMTS.com/ManufacturingExplorers.

To read the rest of the Energy Issue of MT Magazine, click here.