I have been doing business in Brazil for more than 50 years. I lived and went to school there and still visit at least twice every year. Every time I go back, Brazil surprises me. No matter how much I follow the news or talk with my contacts over the phone, once I am there, I realize I have missed something by looking at it from a distance.

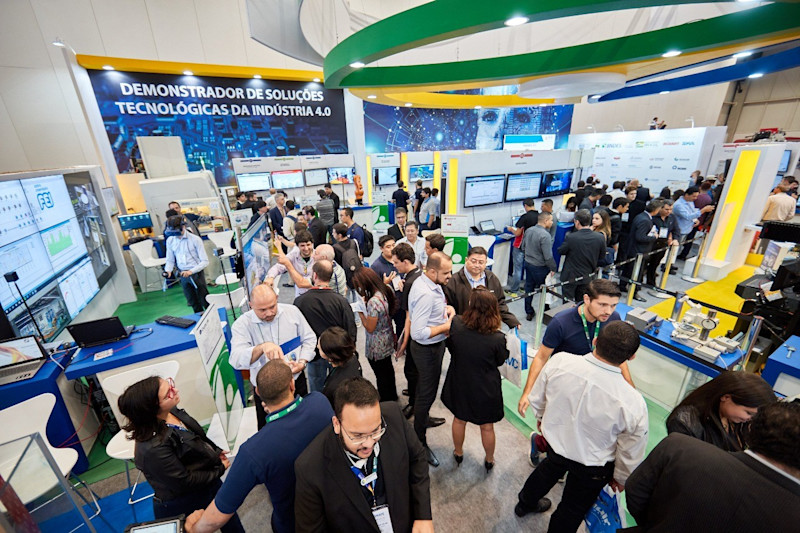

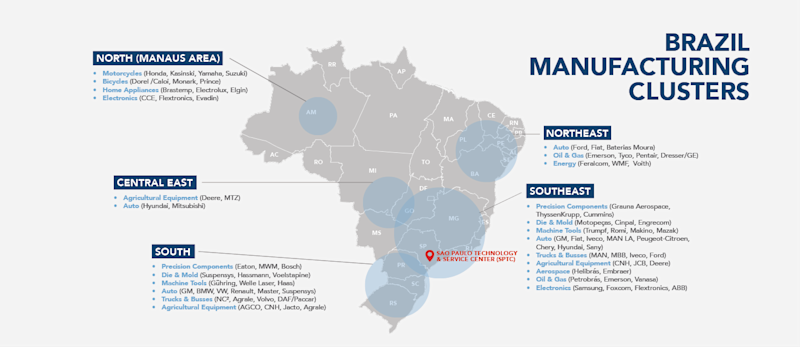

The recent EXPOMAFE 2019 (May 7-11) was in Sāo Paulo. This manufacturing technology trade show—with an area of 592,000 SF and attendance of 55,000 visitors—provided a glimpse of a new trend for the manufacturing industry in Brazil: collaboration. Traditionally, Brazilian companies have been individualistic organizations that kept their process technologies under lock and key. This is changing—and quickly. Most exhibitors included alarge number of co-participants at their booth, demonstrating a team approach to providing solutions that benefit their common customers. The result was an astonishing exchange of experiences and knowledge that encouraged customer investment.

This change in approach is welcome at this juncture of industrial growth in Brazil. After years of a shrinking economy, poor productivity, and high manufacturing costs, this new trend will allow Brazilian entrepreneurs to become more competitive by adopting shared technologies, emulating what the rest of the industrial sector is doing around the globe.

Various factors have allowed this to happen:

A more stable government, with more clearly defined policies. Despite your political views, it is better to know what is in store for the future than to live with uncertainty and sudden changes every week.

Policies are moving away from protectionism. With the reduction, or even exemption, of import duties for certain capital goods, industry can adopt equipment and software that will put them on par with the rest of the world.

Providing incentives for adopting technology. Several industrial segments are now able to invest in smart manufacturing technologies while enjoying federal and state tax breaks. These industries include the automotive (Rota 2030 Program) and the die & mold industries.

The IHS Markit Brazil Manufacturing PMI in the last six months is trending up.

A recent study by the Brazilian Confederation of Industry (CNI) of investment plans for the transformation of industry showed a definite trend in adopting digital factories and smart manufacturing technologies.

EXPOMAFE 2019 provided a cross section of the key international players, eager to participate in the Brazilian market. Many of these global suppliers of manufacturing technology equipment already have some direct presence in Brazil. They are truly solution providers, and this is an important factor in their success. The Brazilian manufacturing industry is hungry for better, faster, and cheaper ways of producing components and final products, to become more competitive. Exhibitors showcased a variety of enhanced productivity ideas and tools that could be implemented right now! A good example of this was the Advanced Manufacturing Cluster sponsored by ABIMAQ, AMT’s counterpart organization in Brazil. As part of the cluster, industry groups, research centers, universities and technical schools created various teams, each with one technology segment in mind. They provided a harmonious demonstration of how these technologies can be implemented immediately, be they at a modern plant or at a facility with many legacy machines.

An “Idea Park” venue presented a variety of topics that focused on practical ways of addressing issues on the factory floor. Attendees had the opportunity to hear Tim Shinbara, AMT’s vice president of technology, speak on “Transformative Technologies: Impacts to Manufacturing, Services, and Business Models” at the Idea Park and at a workshop at IMT – Instituto Maua de Tecnologia.

AMT played an integral part in disseminating manufacturing technologies. The AMT/USA Pavilion featured members displaying their products and services, highlighting their capabilities to add value to the Brazilian manufacturing industry that are unique, but also compatible with what the local industry needs to be competitive. The AMT Emerging Technology Center showcased PLC and Control manufacturers utilizing MTConnect, illustrating the possibilities for communications, integration, and interconnection of equipment and software. AMT also showed the power of partnerships by working with a large number of local technology companies and educational institutions with whom AMT has a long-established relationship: FACENS and Instituto Maua de Tecnologia.

EXPOMAFE 2019 was a success by any measure. It performed better than the previous edition, with a larger crowd attending (+20 percent) and more floor space (+25 percent). The majority of exhibitors reported higher quality leads and inquiries, not to mention more orders taken on the show floor.

If that does not make you want to include Brazil on your radar screen, I don’t know what will. It is not too soon to think about being part of EXPOMAFE 2021 and to figure out a way to engage in this somewhat hidden—but profitable—market.

Make sure to reach out to resources that can help you take the proper actions to pursue this market. Don’t hesitate. Contact Achilles Arbex at AMT Brazil (aarbex@AMTonline.org) or Ed Christopher at AMT HQ (echristopher@AMTonline.org) today and let them show you the way.

Contact Mario Winterstein at mwinterstein@ibdgi.com.