In case you haven’t heard me mention it before, AMT has a small, mobile, manufacturing cell named the Pop-Up Shop – but we usually just refer to it as the test bed. It’s a small manufacturing cell on a wheeled, 8-gauge steel workbench with its own secluded wireless network and uninterrupted power supply so it can keep functioning while being wheeled from outlet to outlet.

The test bed serves several purposes.

Customer Service

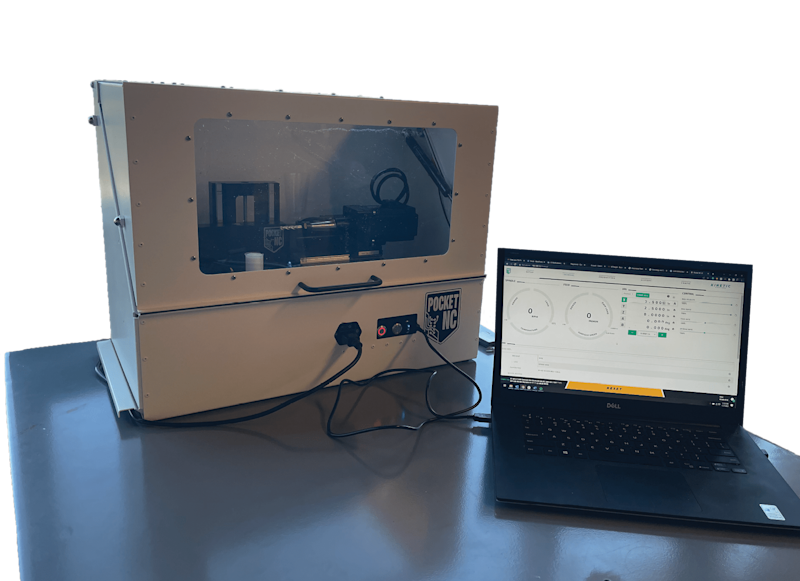

The first purpose is customer service for what is, in my humble-but-indisputable opinion, AMT’s greatest product: MTConnect. If there’s manufacturing technology on that workbench, it’s spittin’ MTConnect. This setup allows us to test and monitor how the standard functions, giving us a strong understanding of what users experience and what their needs might be. These tech include: Stumpy, a children’s DIY Arduino-powered robot arm with a payload capacity that can barely support its own weight; Mickey, a 7-joint cobot straight out of China; and the pièce de résistance: a Pocket NC desktop 5-axis horizontal milling machine named Scooter. The test bed is also used as an educational tool for AMT employees, but I’m kind of failing in that regard.

Internal Education

Now, allow me to spill some tea right quick. Every now and then I hear someone – and not some kid who doesn’t know any better, but, in some cases, someone who’s been in the industry longer than Pelosi’s been on the Hill – refer to a 5-axis horizontal milling machine as a 3D printer! I kid you not. That’s no 3D printer! I mean at least a high schooler will point to the end mill and ask, “Is that some sort of drill bit?” Well, it’s not a drill bit. Obviously. But at least they aren’t confidently declaring a piece of subtractive technology additive! Besides, this is the kind of work I love doing with AMT on our test bed – educating young people, newcomers, and even industry veterans!

So, why a CNC machine and not a 3D printer? Look, if you were sitting at the front desk of AMT’s headquarters and somebody called and asked, “What is manufacturing technology?” How would you answer? Sure, 3DP/AM is popular right now, but – assuming you’re reading this at home, in a coffee shop, in the office, or on the toilet – look around you. I’m willing to bet less than 1% of the objects around you were 3D printed. If you’re reading this in the shop, put this down and get your hands back on the e-stop. Point is: Even with all the hype, AM is still an awful representation of the current state of the revenue-generating (read: parts-making) manufacturing industry.

Proof of Concept

Many manufacturers – whether they are mom-and-pop job shops or full-on government contract facilities for DOD work – are hesitant to implement new technologies they have little familiarity with, and they don’t want to invest their dollars into technology that they don’t know how to use – or if they can even be productive with it.

Enter: the test bed! At AMT, we don’t make parts or sell them. We are not a production facility, dealer, or distributor. Yet we recognize the importance of this technology, so we found the funds to throw together a basic test bed, which includes a 5-axis CNC and a 7-joint collaborative robot.

If we can do it, there is no reason you can’t. If you’d prefer to experiment with our test bed before spending money on new technology, then you are welcome to come to our office in McLean, Virginia, or the Monterrey Tech Center in Mexico, where you can try a robot, see how MTConnect works, or arrange to borrow our technology to get the hang of it.

More information on AMT’s Pop-Up Shop test bed was published in NIST Advanced Manufacturing Series 100-24 “Proceedings of the 10th Model-Based Enterprise Summit (MBE 2019)” report, pages 140-144. It can be downloaded for free at DOI.org/10.6028/NIST.AMS.100-24.

If you have any questions about this information, please contact Stephen at slamarca@AMTonline.org. For more LaMarkable content, stream Seasons One and Two of “Road Trippin’ with Steve” now on IMTS.com/plus.