Most AMT members are familiar with the pillars of AMT’s Manufacturing Mandate, but few know its origin and the role it plays in advancing the interests of our members and the manufacturing technology industry in government policymaking.

A short history

The country was in a recession and the automotive industry was in crisis when AMT President Doug Woods came on board in 2009. Like today, there was an increasing focus on manufacturing to get us out of that challenging time. Always a manufacturer first, Woods was familiar with the lack of coordination of government programs and services to help manufacturers. He knew that the lack of a collaborative and efficient national manufacturing strategy was harming economic growth and competitiveness.

Woods’ approach to sounding the alarm was turning up the voice of the manufacturing technology industry. The Manufacturing Mandate, officially released in 2009, was created to help manufacturers engage with their lawmakers on important issues and connect those lawmakers back to the industry and AMT. It emphasized the importance of a partnership between government, industry, and academia to revitalize the manufacturing sector and promote economic growth.

“Our members are the best advocates,” says Woods. “AMT has several subject matter experts who regularly advise government officials and their staff on policy and legislation, but it’s the manufacturers who can best tell their stories of the impact on their businesses and workers.”

AMT’s strength in advocacy comes from its members and the team of AMT industry experts who regularly interact with policy influencers, departments, agencies, and congressional staff to educate and inform on the manufacturing industry’s issues.

Picked up widely by the business and manufacturing press, the Manufacturing Mandate was described as: “a plan for advancing American manufacturing in the next decade,” “a national mandate to create a strong foundation for sustained economic growth,” and “a coherent national manufacturing strategy that emphasizes innovation.”

Pillars of the Manufacturing Mandate

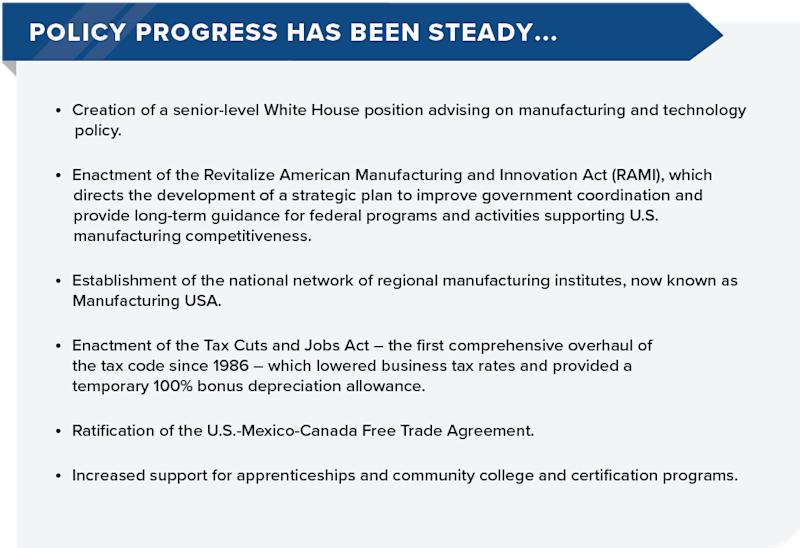

Although the Mandate’s main pillars have not changed over the years, its tactical recommendations are revised depending on legislation and action circulating in Congress and the administration.

The Manufacturing Mandate calls for a coordinated manufacturing policy that:

Incentivizes R&D and innovation in new products and manufacturing technologies.

Levels the playing field and increases the global competitiveness of U.S. manufacturers.

Builds a better educated and trained Smartforce.

Tactical policies supporting these pillars include improving the R&D tax credit and making it permanent, revising SBA and government lending requirements to make loans more accessible to small manufacturers, lowering business taxes, reducing overburdensome regulations, implementing more favorable U.S. export control policies, and strengthening intellectual property and cybersecurity protections. Smartforce recommendations include supporting a national manufacturing skills certification program, mainly as an industry stakeholder organization supporting the National Institute for Metalworking Skills (NIMS); supporting grants, scholarships, and incentives for STEM degrees; and using the Manufacturing Extension Partnerships (MEPs) network as centers of manufacturing excellence to train and support local manufacturers.

Challenges and opportunities remain

Our work continues. Although there have been significant achievements since the release of the Mandate over a decade ago, there are still barriers preventing innovation, a level playing field, and making a dent in the skills gap. Our 2021 advocacy goals include making the bonus depreciation provisions permanent, preserving the lower tax rates enacted in the 2017 Tax Cut and Jobs Act, ensuring resilient supply chains, easing U.S.-China trade tensions while protecting U.S. business interests, incentivizing the adoption of transformational technologies, and building a Smartforce educated and trained on those technologies.

Advocacy resources for members

AMT provides resources for members to help them reach out and build relationships with their members of Congress and local officials. We strongly encourage your engagement because there are no better advocates for manufacturing than the manufacturers themselves. The more manufacturers of all sizes and industries that are engaged, the louder the industry’s voice will be in Washington regarding what is needed to advance and maintain American manufacturing competitiveness in the global marketplace.

The 2021 Manufacturing Mandate will be released in the spring. It will serve as your guide to understanding the issues and a great resource to share with your elected officials. Use it as a starting point to tell your own personal story as a manufacturer.