“It is important not to worship what is known, but to question it.”

– Jacob Bronowski

1. Hybrid’s Big Break

My boy Jason Jones, CEO of Hybrid Manufacturing Technologies, announced halfway into the lunch hour on Tuesday of IMTS 2022 that they just received some big investment bucks from Nikon. “Nikon established the Next Generation Project Division to accelerate the launch of new growth businesses, including advanced materials processing technologies, through synergies resulting from strategic investments and alliances with industry-leading companies worldwide.”

2. Okuma Strives for Energy Efficiency

Okuma America Corp., a leading machine tool manufacturer, announced the launch of their next generation of eco-friendly technology at IMTS 2022. The new machines will use less energy and produce less waste while still providing the same high level of performance. This is a significant advancement in machine tool technology and will help Okuma to continue to lead the way in sustainable manufacturing.

3. FANUC’s New Sim

At IMTS 2022, FANUC demonstrated its new NC Reflection Studio software, which allows users to interactively create, edit, and optimize CNC programs. NC Reflection Studio is said to offer a more intuitive user interface and improved performance compared to traditional numeric control programming methods.

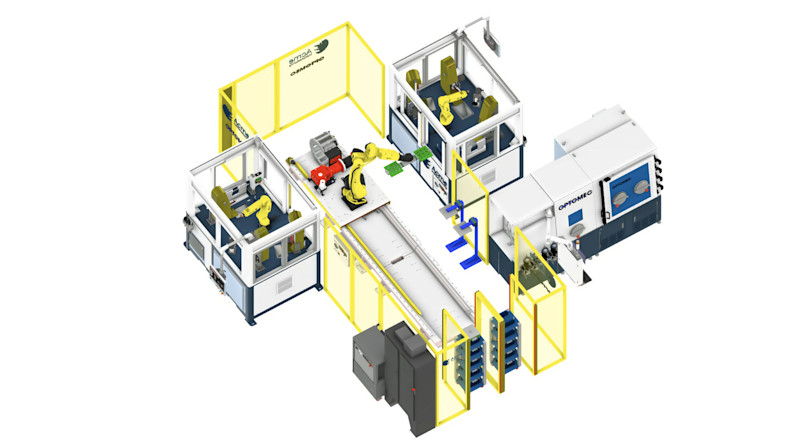

4. Blisk Repair Cell

Optomec developed an automated aviation compressor blade repair work cell that incorporates advanced vision and adaptive tool paths. The cell is designed to repair blades that have been damaged by foreign object debris. The vision system is used to identify the location of the damage and to generate a repair plan to guide the cell's robotic arm, which is equipped with a variety of tools, to repair the blade. The cell is also equipped with a laser scanner to scan the blade before and after repair to ensure that the repair is complete.

5. Collaborative Robot Without the Cobot

Veo Robotics exhibited their FreeMove 3D Safeguarding System for human-robot collaboration at IMTS. The coolest part? No cobot necessary! Veo gives you the full reach, speed, and payload capacity of a standard industrial robot without watering down the performance specs to make it safe(r) to use without a cage.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/