“Capital intensity is inversely proportional to innovation.”

– Kevin Czinger, CEO, Divergent

1. ‘Government Motors’ Back at It

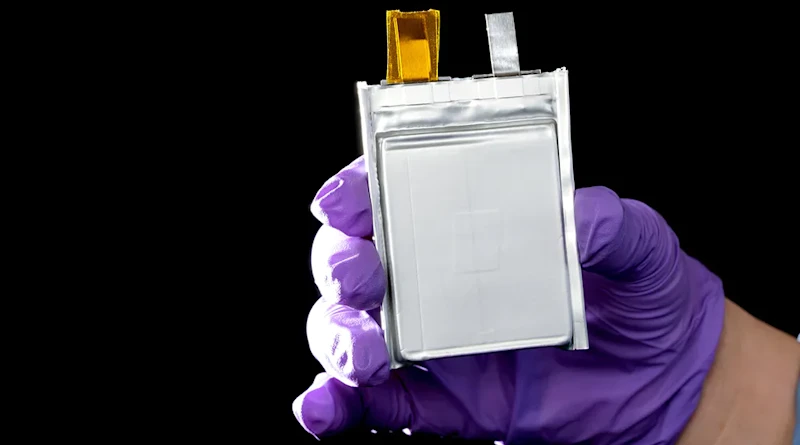

The Department of Energy has announced a $105 million loan for General Motors to produce EV batteries at their plant in Ohio. The loan is part of a $2 billion program to support the production of advanced battery cells for EVs. To be totally fair to GM, “the same program previously made low-cost loans to Tesla Inc, Ford Motor Co., and Nissan, including some funding for electric-vehicle battery production.” I can’t help but get flashbacks of the bailouts … Tough times, man.

2. France Is Taking Off With AM

The Aerospace Development Facility (ADF) in Toulouse, France, is now using additive manufacturing (AM) to produce metal parts for aircraft. The facility is using a Renishaw RenAM 500Q multi-laser additive manufacturing system to produce parts from Inconel 718, a 90-plus-year-old, nickel-based superalloy. The system is said to be the first of its kind in the aerospace industry. The facility is also using a Renishaw RenAM 500M multi-material additive manufacturing system to produce parts from titanium.

3. Snapdragon-Powered AMRs

The Snapdragon isn’t just for smartphones and the latest in consumer electronics. It’s also good for advanced robotics (news to me – seriously)! ForwardX Robotics, a leading developer of autonomous mobile robots (AMRs), has partnered with Qualcomm Technologies Inc., a subsidiary of Qualcomm Inc., to develop new AMRs. The two companies will collaborate on the development of Qualcomm Snapdragon-powered AMRs, which will be designed to provide high-performance, energy-efficient computing for advanced robotics applications.

4. The Machinist’s Handbook for 3DP

This book is a comprehensive guide to troubleshooting 3D printers. It covers a wide range of topics, from common problems to more advanced issues. The book is well organized and easy to follow, making it a valuable resource for anyone who owns or is considering purchasing a 3D printer.

5. Automation for Medical

This article discusses how a small medical shop has embraced automation in order to improve efficiency and quality. The shop, which specializes in small batch production, has installed a number of automated machines and systems, including a robotic arm, an automated filling machine, and a machine that can inspect and sort pills. The shop has also implemented a number of quality control measures, such as regular testing of products and careful inspection of raw materials. As a result of these changes, the shop has been able to increase its production capacity and reduce its costs.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/