“The fate of the Empire rests on the outcome of this battle. Let each man do his utmost.”

– Japanese naval Z ensign, circa 1905

1. Smooth Operator

Dude, not gonna lie – I listened and looked up the lyrics to the track by Sade to throw a reference in here, but I got nothing. Song slaps though! “Slicing through a solid can turn out a continuous band of liberated material or a disorderly sequence of fractured shards. Now researchers have shown that there is a universal transition between these two different ways materials come apart when cut. … The theory is supported by new experiments with several different plastics as well as previous data from experiments on other materials. This new understanding may allow manufacturers to design tools that achieve a better surface finish.”

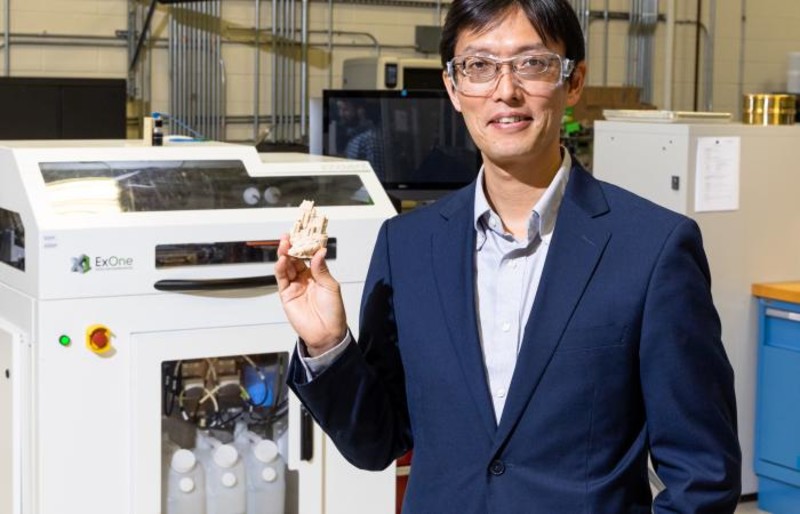

2. Exceptionally Strong Sand Castles

“Researchers at Oak Ridge National Laboratory (ORNL) have announced the development of a novel water-soluble plastic binder that can be added to 3D printing materials and jetted into parts with ‘exceptional strength.’ By tweaking a high-amine content, low molecular weight polyethyleneimine (PEI), the ORNL team has been able to tailor its properties in a way that doubles its strength compared to conventional binders. To showcase the capabilities of their new material, the scientists have already used it to bind and strengthen silica sand, before 3D printing it into a bridge capable of holding 300 times its own weight.” Do you think if you superheat it – like literally nuke it – then it will turn into exceptionally strong glass? I’ll sit down.

3. Boston Dynamics Has Competition

Movie time! “It’s a car, quadruped, and humanoid. Our (ETH Zürich) wheeled-legged robot performs exceptional locomotion skills with reinforcement learning driving at speeds of up to 6.2 m/s (22.32 km/h or 13.87 miles/h), overcoming obstacles, and standing up on two legs!”

4. The Future of Mass Production Additive

Double feature! Yes, “mass production” is still a stretch, but you can’t deny Prusa’s Automated Farm System is sweet! “Prusa PRO AFS is an automated 3D print farm featuring new CoreXY Original Prusa 3D printers. It's our next-generation solution for rapid prototyping and small-batch production with smart task scheduling, Prusa Connect farm management software, automatic print collection & delivery mechanisms, hot-swapping capabilities and simple maintenance. Prusa PRO AFS live demonstration is currently on display at EXPO 2020 Dubai (until March 31st, 2022).” Now I just need a ticket to Dubai!

5. Large-Format Additive Without an Arm

Sure, there are plenty of big ol’ 3D printers available on the market. However, a lot of these massive machines actually have rather small work envelopes. They have their reasons – no disrespect! Some additive processes require a ton of behind-the-scenes wizardry to make quality parts, depending on material and application parameters. Other large prints can’t typically be done in a machine but rather require AM EOAT implemented on a robot. Not this one! Here we have a big ol’ printer for big ol’ prints!

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/