The concept of a digital twin has been around for ages and is most commonly defined as a representation of an object digitally. If you have created a CAD model of a screw, tool, or digital map of the manufacturing process, you have created a digital twin – something we’ve done since the ‘60s. Today, the concept continues to evolve. As CAD and manufacturing systems increase in capability, so too does the value of a digital twin. The ISO/DIN 23247-1 working group, which harmonizes terms, definitions, and applications, is currently working on the harmonization of the digital twin in industrial systems. The International Organization for Standardization defines the digital twin as “<manufacturing> fit for purpose digital representation of an observable manufacturing element with a means to enable convergence between the element and its digital representation at an appropriate rate of synchronization.” The synchronization in the digital twin’s current state can be seen in three areas: simulation and prediction; as-manufactured; and as-used.

Simulation and prediction

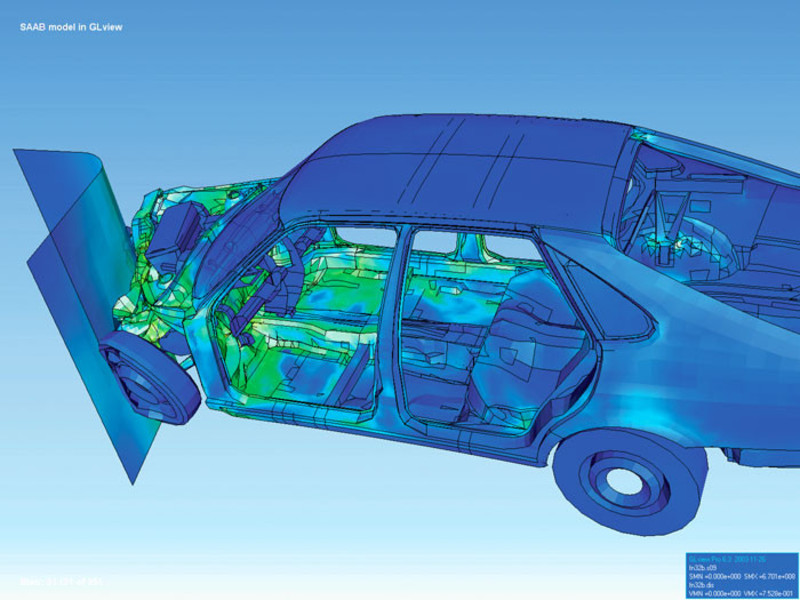

Simulation and prediction is the classic use case of the digital twin. These use cases include static and motion CAD models and answer questions of space, movement, and functionality. Siemens, for instance, tests the digital twin with user-defined conditions in order to determine how the digital twin – and its “real” counterpart – will react: “Based on digital data, developers and the customer can test functions and the operator interface at the virtualization center, even before the machine is built.” The prediction use case comes from finite element models (FEA). FEA models, which are generally based on first principle physics, behave the same as their real counterpart since they are based on the same set of equations. Ideally, they are meant to answer the question, “Will this part work under real operating conditions?” While the results are close and informative, in the real world, each part behaves slightly differently due to variations.

To address these slight variations, we can consider Oak Ridge National Labs’ experiments with a concrete machine tool base. Brent Donaldson of Modern Machine Shop magazine wrote: “Engineers performed an impact test on the area where the machine’s table would be positioned in order to measure the structural dynamics prior to installation of the controller. Later, when the machine is finished, these natural frequencies, modal stiffness values, and damping ratios will influence the machine’s performance, while the embedded sensors will help monitor its vibration and inform overall speed-and-feed selections.” The current evolution of the digital twin for simulation and prediction feeds real-world data into the model. This process reduces the risk of estimation based on first principle physics alone and provides a more accurate prediction.

As-manufactured

As-manufactured use cases incorporate feedback gathered during the manufacturing process, collecting valuable data as the part is transformed from raw material into its final shape. These use cases focus on part features that are created at different steps in the process. Collecting this data can enable a more agile manufacturing process. Optimizing real-time routing modifications based on features that do or do not exist is a business need that will draw on the digital twin. This does require some automation of manufacturing execution data to fully implement, but deriving that from the as-manufactured condition is the first step.

As-used

As-used cases incorporate the final assembly with real-time information about the operating conditions and output of the device. GE Digital’s as-used cases determined that digital twin technology offers benefits such as increased reliability and availability, reduced risk, lower maintenance costs, improved production, and faster-time-to-value. These benefits are a result of lower operation and maintenance costs.

The concept of the digital twin will continue to evolve in the coming decades. The key is to connect the digital models to the physical world through business needs. A more accurate simulation will drive a better performing part. Understanding the as-manufactured part will increase manufacturing agility and reduce unnecessary steps. Visualizing the product as it’s used can drive lower operating maintenance costs.