Inconel and nickel alloys are seriously impressive, but most people don’t realize just how old they are. The Inconel family has been around for over 90 years, and fun fact: “Inconel” is actually a trademarked name. I discovered this at IMTS 2022 when an additive company I was interviewing refused to use the word and instead called it “nickel 718” and “nickel 625” because the trademark had previously caused them trouble. Can you believe it? I mean, come on. It’s been around for more than 20 years. Don’t trademarks expire or something? Well, turns out trademarks stick around as long as the owner keeps using them. Thanks, Legal Zoom, for that tidbit of info.

Let’s Take a Look at Some Notable Nickel Alloys

Take German silver, for example. The name is pretty misleading because it’s neither German nor silver. Back in China, there was this naturally occurring ore composition called “paktong” or “baitong” that people smelted into an alloy. Some German metallurgists then recreated this composition, and that’s how it got the name “German silver.” But it’s about 60% copper, 20% nickel, and 20% zinc. No silver at all! It’s basically just nickel brass. Watchmakers love using it in haute horlogerie (fancy watchmaking), probably for its silvery luster.

Now, let’s talk about Monel, a nickel alloy developed before Inconel. Monel is made up of 52%-67% nickel, with the rest being mostly copper along with a sprinkle of iron, manganese, carbon, and silicon. It’s not even a cupronickel alloy because it has less than 60% copper.

Inconel Etymology

In 1905, a guy named Robert Crooks Stanley, who worked at Inco, the International Nickel Co., discovered Monel. My hypothesis is (couldn’t find any confirmation on the web, so hit me up if you know) Stanley and Inco thought it was significant enough to name after the first chairman of the company, Ambrose Monell. But back in those days, you couldn’t legally name a discovery after someone. So, they took off the last letter and called it “Monel.” Then, when they developed their next big alloy, I’m assuming they combined the company name “Inco” with the last part of their first significant alloy, “Monel,” and bam! Inconel was born. Don’t quote me on this, though. It’s just my speculation.

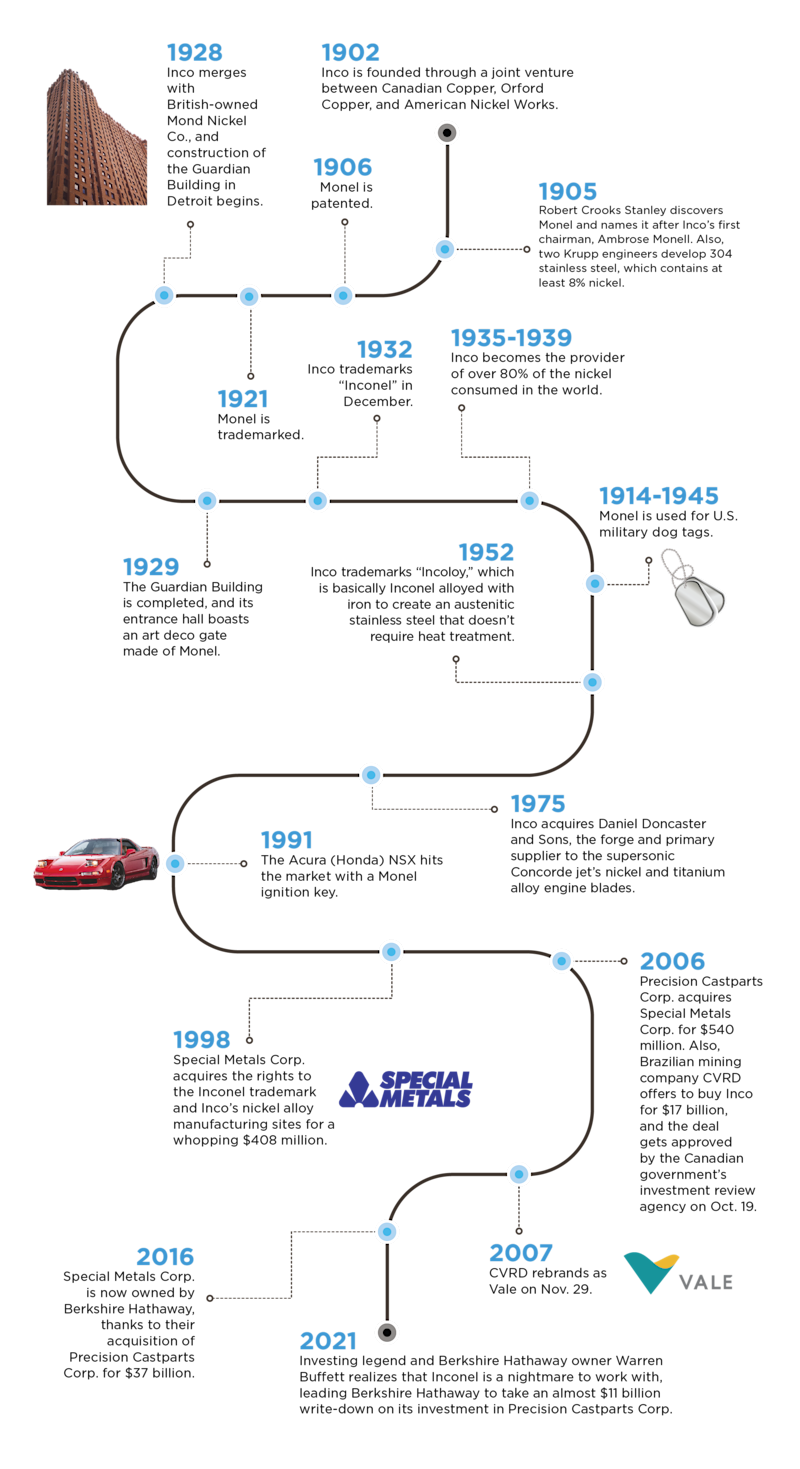

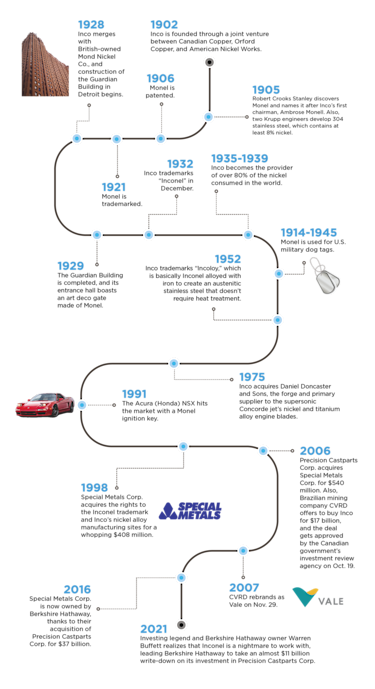

But first: What is Inconel? If you still don’t know, get out from under your rock and check the Wikipedia page. I’m not wasting text space here. But let me tell you this much: Nickel superalloys like Inconel are all the rage in modern manufacturing. You’d think they were just invented in the last decade! They’re incredibly heat and corrosion-resistant, but here’s the catch – they’re a pain to process in manufacturing. Take a pause here and check out the timeline below for the fascinating history of Inconel.

Conclusion

So, the history of Inconel has its ups and downs, but here’s the good news: Thanks to additive manufacturing, it’s no longer impossible to work with. Nickel is one of the easiest base metals to use in additive manufacturing, which is why after over 90 years, it’s finally becoming popular. We can say that metal AM is Inconel’s happy ending, but I think the revolution is just getting started!

To read the rest of the Transportation Issue of MT Magazine, click here.