“You look ridiculous if you dance. You look ridiculous if you don’t dance. So you might as well dance.”

– Gertrude Stein

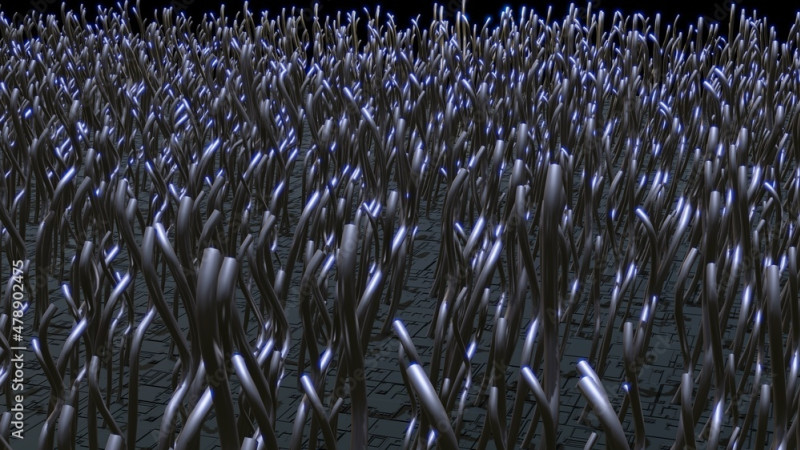

1. Yes, Ceramic Nanowire Is a Thing

Let’s be honest. Nobody likes porosity. It’s like gingivitis in the mouthwash commercials from the ‘90s. MIT-led engineers have reported a simple, inexpensive way to strengthen one of the key materials used in aerospace and energy generation applications. The approach involves the 3D printing of a metallic powder strengthened with ceramic nanowires. The team believes that their general approach could be used to improve many other materials.

2. The Future Starts Today

Everyone is complaining about the current state of the manufacturing workforce. Well, let’s move to problem-solving for tomorrow. Robotics and automation are transforming the way we learn and teach. These technologies offer opportunities for personalized, engaging, and inclusive learning experiences. Automation can be used to provide individualized instruction and feedback, freeing up teachers to focus on more personalized and engaging activities.

3. You Get a CMM! And You Get a CMM!

Selecting the correct CMM is a journey. It is a mix of what is available and what meets your needs. Can this be done in three steps? Well, maybe that is the start of the journey, at least. Don’t forget important nuances with CMMs such as maintenance and consumables. These are even more relevant in situations where CMMs are deployed in areas that are not environmentally controlled.

4. Aerospace Is Always Trying To Be Fancy

Composites continue to make headway in aerospace applications. With a market this big, we’ll be sure to keep an eye on this shift. It boggles my mind how to machine self-healing composites. If you cut it, doesn’t it grow back? Just kidding. In the end, this industry is driving increased reliability and efficiency through new materials, and I like it.

5. Why Can't Robots Have Sweaters?

Well, now they can. The industry is testing the waters by going fenceless with industrial robots. This research uses two layers of conductive yarn sandwiching a lace-like layer of insulation. When the circuit between the layers is complete, the robot receives a signal. Like most technologies, I can see this coupled with other passive technologies to create a space around the arm.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/