“Building a data strategy is like spinning a flywheel. It’s cyclical, iterative, gradual, and perpetual. There is no special line that, if crossed, will deem your organization 'data-driven.' ”

– Michael Bertha

1. A Valet That Won’t Burn Out Your Clutch

Ah, yes! It’s been a great year and you want to take your special someone to a fine Micheline star dinner. The two of you get gussied up in your finest Sunday attire and grab the keys to the little, red, two-seater, garage queen that’s never seen a drop of rain in its life. You fire it to life and give sufficient time for the fluids to circulate and the oil to come to temperature before you dare put any load on the powertrain. During that time, you pick one of your several hand-wound Swiss dress watches to wear and sync it to NIST’s atomic clock. As you pull out of your climate-controlled bay and leave the gated neighborhood to set off to the restaurant, a sudden downpour of anxiety becomes of you. “We’re going to a nice place… parking will likely be valet only! Some teen will certainly frag the friction disc within the transmission’s bell housing! That engine-out repair will be at least five figures!” You cry to yourself internally. If only valet parking was automated…

2. Y’all Need Facility Tours

Manufacturing and machining tours can provide students with insight into how these industries work. The tours can also give students an opportunity to see how their skills can be applied in a real-world setting. My personal favorite key takeaways for facility tours are: there’s almost no place anymore that requires the use of ear plugs (shops are getting quieter), and no matter how advanced the technology is, every plant has a dark and dusty corner housing a loyal Bridgeport knee mill and LeBlond lathe. :)

3. Paper Batteries

I mean not really but hear me out. Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a technique to convert wastepaper from single-use packaging, bags, and cardboard boxes into a crucial component of lithium-ion batteries. This paper waste has a large environmental footprint. The researchers used a process called carbonization to convert the paper into pure carbon. Sounds like they just burned trash, right? Well, they didn’t, they electrocuted it. Kinda.

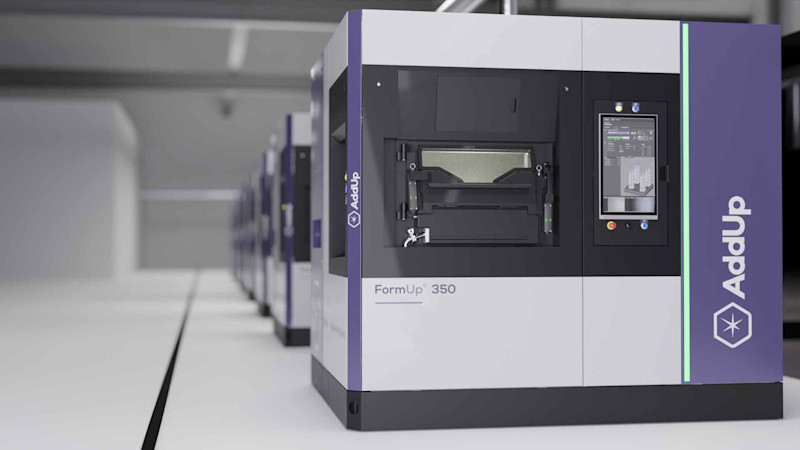

4. Prototyping to Mass Production

AddUp Solutions and Dassault Aviation are working together to transition metal AM technology for aeronautics from “prototyping” to “mass production.” To accomplish this, additive technology must be optimized in terms of quality, reproducibility, and productivity to consider the mass production of metal parts that will then be integrated into aircraft. AddUp, a machine and additive parts manufacturer, oversees the development of a new production system based on interoperability and process robotization.

5. Cybersecurity and the FBI

This Thanksgiving I had eight hours to listen to podcasts, thanks to the hellscape that is I-95 between DC and Richmond, VA. In that time I learned a ton from Chris Tarbell, the FBI agent who took down the Silk Road (the original dark web black market), and his cybersecurity takeaways from his time in the FBI.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/